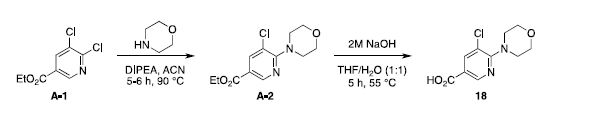

Preparation of 5-chloro-6-morpholinonicotinic acid (18)1

A solution of ethyl 5,6-dichloronicotinate (A-1, 1.1 g, 5.0 mmol), N,N-diisopropylethylamine (DIPEA, 0.97

g, 7.5 mmol) in acetonitrile (3.0 mL) was treated with morpholine (0.48 g, 6.0 mmol). The mixture was

stirred for 6 hours at 95 °C. The complete conversion of the starting material could be detected by

observing a change of the color from yellowish to deep orange. After complete conversion, the mixture was

evaporated to dryness, the residue diluted with water (20 mL), and extracted with dichloromethane (3x20

mL). The combined organic layer was dried over sodium sulfate and evaporated under reduced pressure to

yield 1.31 g (97 %) of A-2 as a red oil. The product was identified by LC/ESI-MS analysis and used for the

next synthetic step without further purification.

The ester A-2 (1.31 g, 4.83 mmol) was dissolved in a tetrahydrofurane/water mixture (1:1, 4.0 mL) and

treated with 2.0 M sodium hydroxide (0.33 g, 5.80 mmol). The reaction mixture was stirred for 5 h at 55 °C.

After complete conversion, the mixture was cooled to room temperature, diluted with water (20 mL) and

extracted with ethyl acetate (3x20 mL). The water layer was neutralized with an aqueous solution of

hydrochloric acid (2.0 N) until a white precipitate was observed. The product was collected by repeated

filtration and evaporation. The combined product fractions were dried at 70 °C yielding 1.17 g (100 %) of

18 as a white solid,

A solution of ethyl 5,6-dichloronicotinate (A-1, 1.1 g, 5.0 mmol), N,N-diisopropylethylamine (DIPEA, 0.97

g, 7.5 mmol) in acetonitrile (3.0 mL) was treated with morpholine (0.48 g, 6.0 mmol). The mixture was

stirred for 6 hours at 95 °C. The complete conversion of the starting material could be detected by

observing a change of the color from yellowish to deep orange. After complete conversion, the mixture was

evaporated to dryness, the residue diluted with water (20 mL), and extracted with dichloromethane (3x20

mL). The combined organic layer was dried over sodium sulfate and evaporated under reduced pressure to

yield 1.31 g (97 %) of A-2 as a red oil. The product was identified by LC/ESI-MS analysis and used for the

next synthetic step without further purification.

The ester A-2 (1.31 g, 4.83 mmol) was dissolved in a tetrahydrofurane/water mixture (1:1, 4.0 mL) and

treated with 2.0 M sodium hydroxide (0.33 g, 5.80 mmol). The reaction mixture was stirred for 5 h at 55 °C.

After complete conversion, the mixture was cooled to room temperature, diluted with water (20 mL) and

extracted with ethyl acetate (3x20 mL). The water layer was neutralized with an aqueous solution of

hydrochloric acid (2.0 N) until a white precipitate was observed. The product was collected by repeated

filtration and evaporation. The combined product fractions were dried at 70 °C yielding 1.17 g (100 %) of

18 as a white solid,

m.p. 185.2–186.2;

1H NMR (500 MHz, DMSO-d6) δ (ppm) 3.45 (t, J = 5.04 Hz, 2xCH2,4H), 3.72 (t, J = 4.41 Hz, 2xCH2, 4H), 8.08 (d, J = 1.89 Hz, CH, 1H), 8.66 (d, J = 1.90 Hz, CH, 1H), 13.01(s, CO2H, 1H). 13C (125 MHz, DMSO-d6) δ (ppm) 48.9 (2xCH2), 66.1 (2xCH2), 119.4, 139.7, 147.5, 159.3,

165.4;

165.4;

LC/ESI-MS (m/z): 243.28 [M+H]+; Purity: 100.0 % (N).

Colandrea, V. J.; Doherty, G. A; Hale, J. J.; Huo, P.; Legiec, I. E.; Toth, L.; Vachal, P.; Yan, L. (3,4-

Disubstituted)propanoic carboxylates as S1P (EDG) receptor agonists. PCT Int. Appl. WO2005058848A1, 2005 (Merck & Co., Inc.).

Disubstituted)propanoic carboxylates as S1P (EDG) receptor agonists. PCT Int. Appl. WO2005058848A1, 2005 (Merck & Co., Inc.).

Supporting Information

https://s3-eu-west-1.amazonaws.com/pstorage-acs-6854636/.../jm500729a_si_001.pdf

No comments:

Post a Comment