Phenytoin sodium, Dilantin, is a commonly used antiepileptic. Phenytoin acts to suppress the abnormal brain activity seen in seizure by reducing electrical conductance among brain cells by stabilizing the inactive state of voltage-gated sodium channels. Aside from seizures, it is an option in the treatment of trigeminal neuralgia in the event that carbamazepine or other first-line treatment seems inappropriate.

It is sometimes considered a class 1b antiarrhythmic.

Phenytoin, 5,5-diphenylimidazolidinedione is synthesized in two different ways. The first involves a base catalyzed addition of urea to benzil followed by a benzilic acid rearrangement (1,2 phenyl migration) to form the desired product. This is known as the Biltz Synthesis of phenytoin.

| Systematic (IUPAC) name | |

|---|---|

| 5,5-diphenylimidazolidine-2,4-dione | |

| Clinical data | |

| Trade names | Dilantin |

| AHFS/Drugs.com | monograph |

| MedlinePlus | a682022 |

| Pregnancy cat. | |

| Legal status | |

| Routes | Oral, parenteral |

| Pharmacokinetic data | |

| Bioavailability | 70-100% oral, 24.4% for rectal and intravenous administration |

| Protein binding | 90% |

| Metabolism | hepatic |

| Half-life | 6–24 hours |

| Excretion | Primarily through the bile, urinary |

| Identifiers | |

| CAS number | 57-41-0 |

| ATC code | N03AB02 |

| PubChem | CID 1775 |

| DrugBank | DB00252 |

| ChemSpider | 1710 |

| UNII | 6158TKW0C5 |

| KEGG | D00512 |

| ChEBI | CHEBI:8107 |

| ChEMBL | CHEMBL16 |

| Chemical data | |

| Formula | C15H12N2O2 |

| Mol. mass | 252.268 g/mol |

Dilantin (phenytoin sodium injection, USP) is a ready-mixed solution of phenytoin sodium in a vehicle containing 40% propylene glycol and 10% alcohol in water for injection, adjusted to pH 12 with sodium hydroxide. Phenytoin sodium is related to the barbiturates in chemical structure, but has a five-membered ring. The chemical name is sodium 5,5-diphenyl-2, 4-imidazolidinedione represented by the following structural formula:

Step by step to synthesis Dilantin

The synthesis processes of 5,5-diphenylhydantion are as follows:

The processes could be divided into three steps:

1. Preparation of Benzoin

2. Preparation of Benzil

3. Preparation of 5,5-diphenylhydantion

STEP 1

- Molecular formula: C14H12O2

- Molar mass: 212.244

- CAS Registry Number: Not available

- Appearance: Benzoin, 99%; Benzoin, 99%; white to light yellow crystals with a faint, sweet, balsamic odour; light yellow powder or crystals with a camphor-like odour

- Melting point: 134 to 136 °C

- Boiling point: Not available

- Solubility: Water, 300 mg/L (25 deg C), 300 mg/L (25 deg C)

- Safety sheet: Not available

- Spectra: ChemSpider (1H NMR, 13C NMR), NMRShiftDB 13C NMR, also check on SDBS.

Benzoin is the precursor of the antiepileptic medicine, Dilantin (Phenytoin).

Benzoin is also a white crystal perfumery. The DL-type is a hexagon monoclinic rhombic crystal. Both D-type and L-type are needle-shape crystals.

In this experiment, a benzoin condensation of benzaldehyde is carried out with a biological coenzyme, thiamine hydrochloride, as the catalyst.

Reaction equation

Vitamin B1 is a coenzyme. It may replace the extremely toxic substance, sodium cyanide, as the catalyst, is benzoin condensation. The structure of Vitamin B1 is as fallow:

Mechanism

Step 1

Step 2

Step 3

IR, NMR, 13C NMR.......................https://instruct.uwo.ca/chemistry/283g/labs/Experiment%202/Spectral%20Data%20Exp%202%20_2007.pdf

Chemical

1. Vitamin B1 hydrochloride: 1.20g

2. Benzaldehyde: ~6.24g

3. Ethanol 95%: 12mL

4. Sodium hydroxide solution: 2.5M 4.0mL

Procedure

1. Dissolve 1.20g thiamine hydrochloride (Vitamin B1) into 4.0mL water in a 125mL flask.

2. When Vitamin B1 is dissolved, add 12.0mL 95% ethanol.

3. Stopper the flask and cool the solution with a ice bath, slowly add 4.0mL of cold 2.5M sodium hydroxide to the flask, and make pH of the solution is about 10~11.

Vitamin B1 solution turns into yellow after added sodium hydroxide soludtion

4. Rapidly add ~6.24g benzaldehyde to the reaction mixture and sufficiently mix the solution. Stopper the flask and allow it to stand at room temperature for 24 hours.

The appearance at the first

The appearance after 6 hours

The appearance after 9 hours

The appearance after 24 hours

5. At the end of the reaction period, the benzoin should have separated as fine while crystals.

6. When the crystallization is completed, collect the crude product by filtration. And wash is with some cold water and ethanol.

The crude benzoin (still containing some Vitamin B1 and some NaOH)

7. Recrystallize the product from 95% ethanol.

8. Air dry the final product.

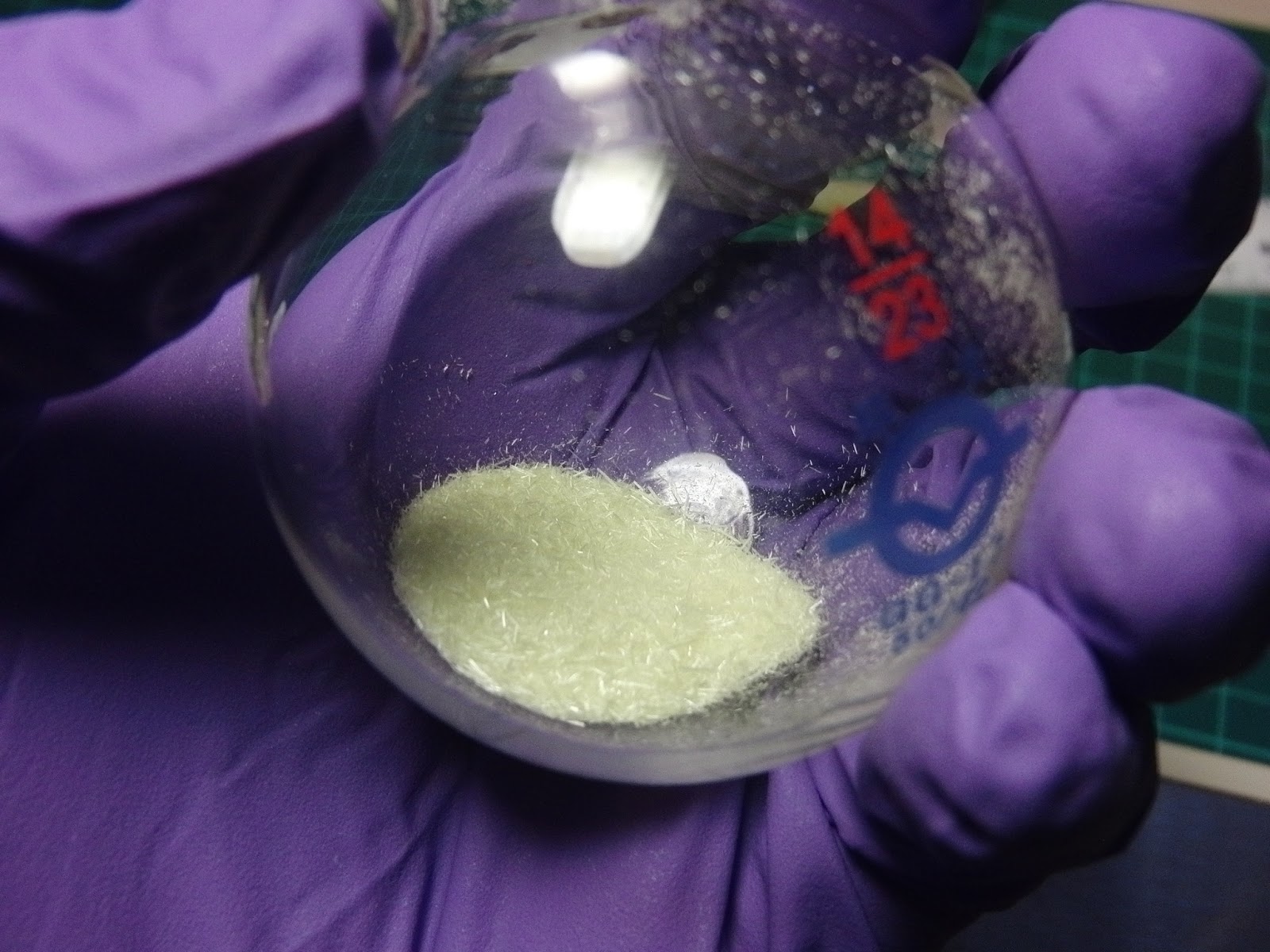

The final product should be white crystals

Notes

1. Vitamin B1 exists in the form of thiamine hydrochloride. It is stable in the acidic condition, but it absorbs water easily, and it is a heat-sensitive reagent, the thiamine in aqueous solution is oxidated easily by oxygen in the air. The rate of oxidation may be accelerated by light and some ions such as cupric ion, ironic ion and magnesium ion. It should be stored in a refrigerator. Since the thiazole ring is broken easily in basic solution, both the aqueous solutions of thiamine hydrochloride and sodium hydroxide should be cooled thoroughly with an ice bath before use.

2. The control of the pH value is the key to the benzoin condensation of benzaldehyde. So the benzaldehyde used for this experiment must be free of benzoic acid. The benzaldehyde must be redistilled before use.

Experimental Record

Weight of benzaldehyde

|

6.11 g

|

Weight of benzoin after recrystallization and air dried

|

1.69 g

|

Yield

|

27.7 %

|

STEP 2

α-Diketones are very useful in the preparation of cyclic compounds of great value. Benzil, an α-diketone, is prepared by the oxidation of an α-hydroxyketone, benzoin. This oxidation can easily be done with mild oxidizing agent. In the experiment, the oxidation is performed with ironic chloride hexahydrate.

(See also: Preparation of Benzoin - Synthesis of Dilantin )

Reaction equation

Possible Mechanism

Step 1

Step 2

1H-NMR: Benzil300 MHz, CDCl3delta [ppm]mult.atomsassignment7.50m (d)4 H2-H, 2'-H, 6-H, 6'-H7.64m (dd)2 H4-H, 4'-H7.95m (dd)4 H3-H, 3'-H, 5-H, 5'-H

| 1H-NMR: Benzil | |||

| 300 MHz, CDCl3 | |||

| delta [ppm] | mult. | atoms | assignment |

| 7.50 | m (d) | 4 H | 2-H, 2'-H, 6-H, 6'-H |

| 7.64 | m (dd) | 2 H | 4-H, 4'-H |

| 7.95 | m (dd) | 4 H | 3-H, 3'-H, 5-H, 5'-H |

| 13C-NMR: Benzil | |||

| 75.5 MHz, CDCl3 | |||

| delta [ppm] | assignment | ||

| 129.0 | CH arom. | ||

| 129.8 | CH arom. | ||

| 133.0 | CH arom. | ||

| 154.8 | C quart. arom. | ||

| 194.5 | C=O | ||

| 76.5-77.5 | CDCl3 | ||

| IR: Benzil | |||

| [KBr, T%, cm-1] | |||

| [cm-1] | assignment | ||

| 3064 | arom. C-H valence | ||

| 1660 | C=O valence, ketone | ||

| 1594, 1579 | arom. C=C valence | ||

GC

GC: pure productcolumnDB-1, L=28 m, d=0.32 mm, film=0.25 µminleton column injection, 0.2 µLcarrier gasH2, 40 cm/soven90°C (5 min), 10°C/min --> 240°C (30 min)detectorFID, 270°Cintegrationpercent concentration calculated from relative peak area

SEE A PUBLICATION BELOW

IR, NMR..................http://kriemhild.uft.uni-bremen.de/nop/en/instructions/pdf/4002_en.pdf

CHECK THIS PUBLICATON FOR REAL ONES

Chemical

1. Benzoin: 1.20g

2. Ironic chloride hexahydrate: 5.10g

3. Ethanol

4. Acetic acid: ~6mL

Procedure

1. Place 6mL of glacial acetic acid, 3mL of water, 5.1g FeCl3˙6H2O and a stir bar in a 100mL round-bottom flask fitted with a reflux condenser.

I used a air condenser because the boiling point of the distillate is high

and it also safe more energy

2. Heat gently the mixture to boil and shake the mixture occasionally. Stop heating and cool the solution slightly.

3. Add 1.20g benzoin to the flask and continue to heat. Reflux the mixture 1 hour.

4. Then add 30mL of water to the flask and heat the mixture again. After boil, cool the solution, yellow solid separates. Collect the crude product by filtration, and wash it three times with a small amount of cold water.

After add water

Boil the solution again

Place in an ice bath

5. Recrystallize the crude product from 75% aqueous ethanol (about 30mL).

6. Air dry the product and weight it.

Get 0.80g

Experimental Record

Weight of benzoin added

|

1.20 g

|

Weight of benzil after recrystallization

|

0.80 g

|

Theory weight of benzil

|

1.19 g

|

Yield Rate

|

67.2 %

|

STEP 3

The sodium salt of 5,5-diphenylhygantion, Dilantin, is an anticonvulsant used for the treatment of epilepsy.

The synthesis process of 5,5-diphenylhygantion is as follows:

Reaction equation:

Mechanism:

Chemical

1. Benzil: 0.60 g

2. Urea: 0.36 g

3. Potassium hydroxide solution: ~2mL saturated(~14.8M)

4. Sulfuric acid: 6M

5. Ethanol 95%

Procedure

1. Add 0.60g benzil and 0.36g urea in to a 50mL round-bottomed flask

2. Add 6 mL 95% ethanol and 1~2mL KOH solution.

3. Reflux the mixture with stirring for 2.5 hr.

4. Cool the reaction mixture and remove the sparingly insoluble solid by gravity filtration.

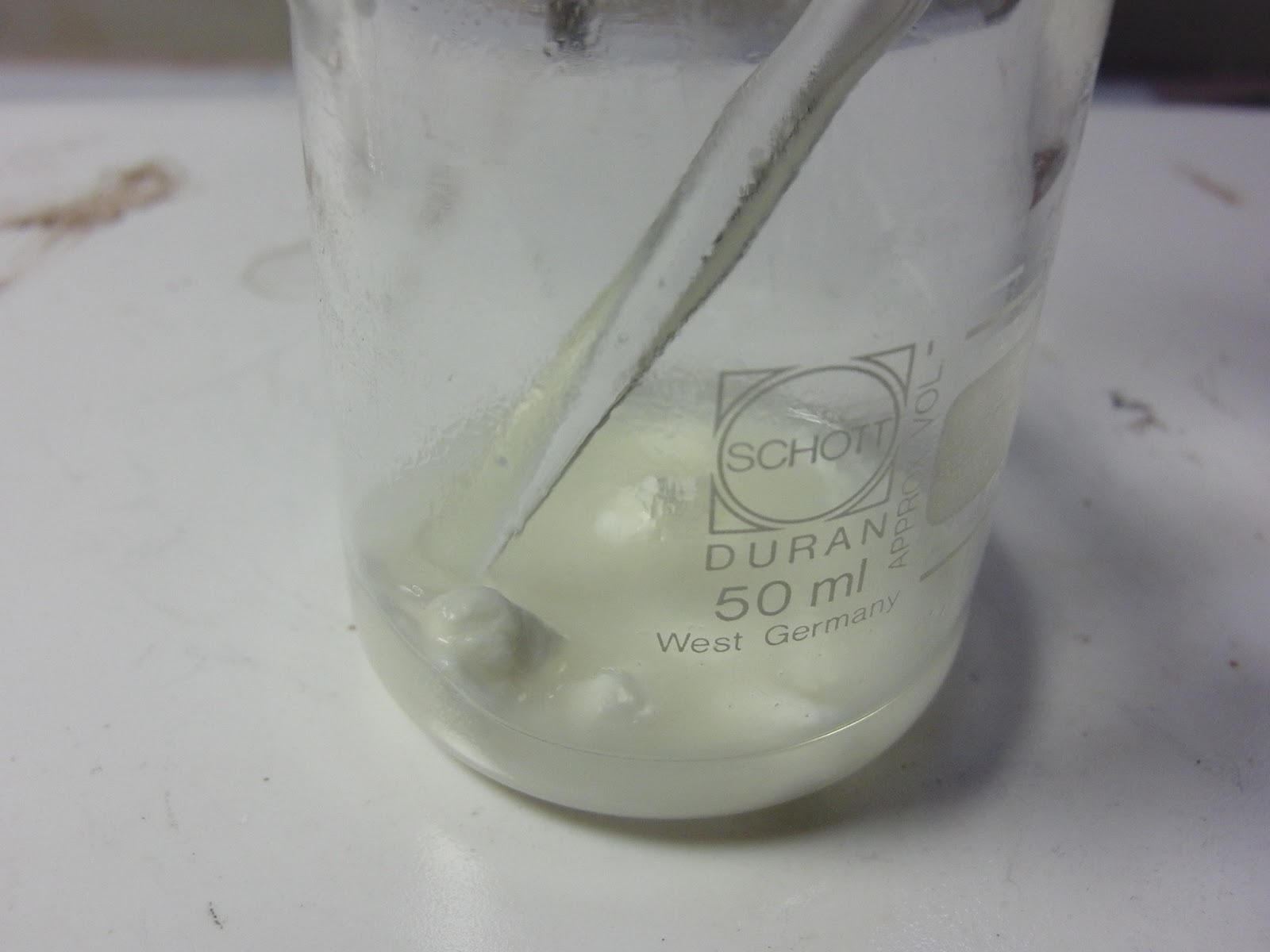

5. Cool the filtrate further in an ice-water bath and acidify the filtrate with 6M sulfuric (pH 1.5~3). The white powdered solid is obtained.

6. Collect the product by filtration, and wash it thoroughly with water to remove the inorganic salt.

7. Recrystallize the crude product from 95% ethanol.

8. The white needle-shape crystal is obtained.

Experimental Record

Weight of benzil

|

0.60 g

|

Weight of final product (Dilantin)

|

0.36 g

|

Theoretical Weight of Dilantin

|

0.72 g

|

Yield

|

50.0 %

|

MASS SPECTRUM

1H NMR

1H NMR

13 C NMR

13 CNMR

IR SECTRUM

MASS SPECTRUM

OTHERS

Synthesis of benzil from benzoin using VOCl3

SYNTHESIS............

http://kriemhild.uft.uni-bremen.de/nop/en/instructions/pdf/4002_en.pdf

DRUG APPROVALS BY DR ANTHONY MELVIN CRASTO .....FOR BLOG HOME CLICK HERE

DRUG APPROVALS BY DR ANTHONY MELVIN CRASTO .....FOR BLOG HOME CLICK HERE

Equipment |

| two-necked flask 250 mL | heatable magnetic stirrer with magnetic stir bar | |||

| gas-filled balloon | adapter with ground-glass joint, ground-in stopcock and hose coupling | |||

| separating funnel | rotary evaporator |

Substances required |

| Educts | Amount | Risk | Safety | |||||

|---|---|---|---|---|---|---|---|---|

| Benzoin | 21.2 g | R | S | |||||

| Oxygen |

| R 8 | S 2-17 | |||||

| Catalyst | Amount | Risk | Safety | |||||

| Vanadium(V) oxychloride |

| 0.174 g | R 14-25-34 | S 8-26-28.1-30-36/37/39-45 | ||||

| Solvents | Amount | Risk | Safety | |||||

| Acetone |

| 100 mL | R 11-36-66-67 | S 2-9-16-26 | ||||

| Acetic acid ethyl ester |

| 250 mL | R 11-36-66-67 | S 2-16-26-33 | ||||

| Diethyl ether |

| ~5 mL | R 12-19-22-66-67 | S 2-9-16-29-33 | ||||

| Others | Amount | Risk | Safety | |||||

| Sodium hydrogen carbonate | ~30 g | R | S | |||||

| Sodium chloride |

| ~60 g | R 36/37/38 | S 24/25-26-36 | ||||

| Magnesium sulfate | R | S | ||||||

| Solvents for analysis | Amount | Risk | Safety | |||||

| Petroleum ether (60-80) |

| R 11-38-48/20-52/53-62-65 | S 9-16-23.2-24-29-33-36/37-62 | |||||

| Methanol |

| R 11-23/24/25-39/23/24/25 | S 1/2-7-16-36/37-45 | |||||

| Dichloromethane |

| R 40 | S 2-23.1-24/25-36/37 |

Simple evaluation indices |

| Atom economy | 92.1 | % | |

| Yield | 59 | % | |

| Target product mass | 12.3 | g | |

| Sum of input masses | 330 | g | |

| Mass efficiency | 38 | mg/g | |

| Mass index | 26 | g input / g product | |

| E factor | 25 | g waste / g product |