Toremifene

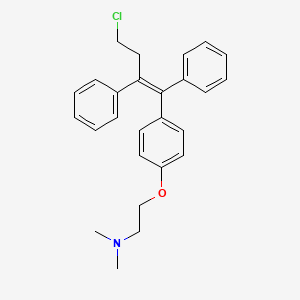

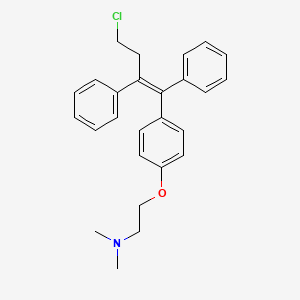

2-[4-[(Z)-4-chloro-1,2-diphenylbut-1-enyl]phenoxy]-N,N-dimethylethanamine

(Z)-2-[4-(4-Chloro-1,2-diphenyl-1-butenyl)phenoxy]-N,N-dimethylethanamine

(Z)-4-Chloro-1,2-diphenyl-1-[4-[2-(N,N-dimethylamino)ethoxy]phenyl]-1-butene

(Z)-Toremifene

2-({4-[(1Z)-4-chloro-1,2-diphenylbut-1-en-1-yl]phenyl}oxy)-N,N-dimethylethanamine

4-chloro-1,2-diphenyl-1-[4-[2-(N ,N-dimethylamino)ethoxy]phenyl]-1-butene

Toremifene; Acapodene; Farestone; Z-Toremifene; Toremifeno; Toremifenum

| Molecular Formula: |

C26H28ClNO |

| Molecular Weight: |

405.95962 g/mol |

cas 89778-26-7

Launched – 1988.Orion (FI), greast cancer

- Citrate, Toremifene, GTx-006

NK-622

- Fareston

- FC 1157a

- FC-1157a

- FC1157a

- Toremifene

- Toremifene Citrate

- Toremifene Citrate (1:1)

- Toremifene, (E)-Isomer

-

- C26H28ClNO · C6H8O7

- Molecular Weight 598.08

Toremifene Citrate

Toremifene Citrate

Toremifene is a first generation selective estrogen receptor

modulator (SERM). Like TAMOXIFEN, it is an estrogen agonist for bone

tissue and cholesterol metabolism but is antagonistic on mammary and

uterine tissue.

The company GTx is conducting phase III clinical trials for the

prevention of prostate cancer in men who have been diagnosed with high

grade prostatic intraepithelial neoplasia (PIN).

Toremifene citrate is an oral

selective estrogen receptor modulator (SERM) which helps oppose the actions of

estrogen in the body. Licensed in the United States under the brand name

Fareston, toremifene citrate is

FDA-approved for use in advanced (

metastatic)

breast cancer. It is also being evaluated for prevention of

prostate cancer under the brand name

Acapodene.

[1]

In 2007 the pharmaceutical company

GTx, Inc was conducting two different phase 3

clinical trials; First, a pivotal Phase clinical trial for the treatment of serious side effects of

androgen deprivation therapy (ADT) (especially vertebral/spine fractures and

hot flashes, lipid profile, and

gynecomastia)

for advanced prostate cancer, and second, a pivotal Phase III clinical

trial for the prevention of prostate cancer in high risk men with high

grade

prostatic intraepithelial neoplasia, or PIN. Results of these trials are expected by first quarter of 2008

[2]

An NDA for the first application (relief of prostate cancer ADT side effects) was submitted in Feb 2009,

[3] and in Oct 2009 the FDA said they would need more clinical data, e.g. another phase III trial.

[4]

Originally developed at Orion, toremifene was subsequently licensed

to Nippon Kayaku in Japan and to Asta Medica (now, part of Meda) in

Germany.

Synthesis

……….

PATENT

http://www.google.com/patents/CN104230723A?cl=en

Toremifene (Toremifene), chemical name (Z)

-4- chloro-1,2-diphenyl–1- [4- (2- (N, N- dimethylamino) ethoxy yl)

phenyl] -1-butene, having the structure I.Toremifene

to tamoxifen (Tamoxifen) analogues with anti-estrogenic activity, can

be used in the treatment of hormone-dependent breast cancer, and its

E-isomer has the presence of estrogenic activity, E isomers toremifene

may counteract anti-estrogenic activity, and therefore isomeric purity

is essential toremifene.Toremifene was

developed in 1983 by the Finnish Famos company, listed in 1996 by the

Orion company in the EU, the trade name Fareston, 2002 to enter the

country, the trade name of toremifene.

RJ Toivola et al., European Patent EP95875,

disclosed in U.S. Patent US4696949A synthetic route toremifene, that

following a synthetic route, the synthetic route to phenol as a raw

material, by acylation, rearrangement, alkyl group and an addition

reaction to give 1,2-diphenyl -1- [4- [2- (N, N- dimethylamino)

ethoxyphenyl]] – 1,4-diol (Compound 5) as the key intermediate, further

HCl in ethanol or hydrochloric acid elimination reaction occurs, then

get toremifene thionyl chloride reaction. The

main problem with this approach is that the elimination reaction of the

compound 5 in ethanol occurs when hydrochloric acid or concentrated

hydrochloric acid, the resulting triaryl alcohol butyrate (Compound 6)

having a Z / E configuration, both the ratio of 1: 2 ~ 2: 1, stereo

selectivity is not high, and there are 5% of the cyclization by-product;

on the Z / E configuration Miyoshi butyric fractional crystallization

of alcohol, you can get pure Z-type Miyoshi butyric alcohol , but the

yield is only 41%; then, Z-type Miyoshi butyric alcohol chlorination

reaction occurs in the action of thionyl chloride, the purified product

toremifene.

U.S. Patent US5491173A also reported another synthetic route toremifene namely the following two synthetic routes. The

route to the aryl ketone (Compound 7) with a phenyl Grignard reagent

addition reaction of ketone carbonyl groups to give triaryl-butanediol

(compound 5), which is the elimination of toremifene and chlorinated

reaction products happen again.

Chinese Patent Publication No. CN1125716A

application reported an efficient synthesis of Z-type Miyoshi butyric

alcohol (compound 6) method, US4696949A compared with the US patent, the

method mild conditions, reduce the acid concentration and reaction

temperature, reaction time, triarylphosphine butanediol (Compound 5) in

concentrated hydrochloric acid or concentrated hydrochloric isopropanol

or ethanol effect of concentrated hydrochloric acid, can be 60-78%

selectivity and 95% yield of type 2 Miyoshi butyric alcohol But after

Publication No. 0 02,126,969 attached eight patent applications after

the inventor repeated experiments show that the technique disclosed in

the patent application programs can not achieve their claimed technical

effect.

Publication No. CN102126969A of Chinese

patent applications through the intermediate Miyoshi butyric alcohol

occurs at a catalytic converter configuration of concentrated

hydrochloric acid, while taking advantage of differences in solubility,

so E- type Miyoshi butyric alcohol continuously into Z-type Miyoshi

butyric alcohol (compound 6) precipitates, thereby undermining the

balance, so that one of the E-type Miyoshi butyric alcohol continuously

into Z-type Miyoshi butyric alcohol (compound 6) to give the Z-Miyoshi

butyric alcohol ( Compound 6) and then get toremifene thionyl chloride

after chlorination. Although to some extent, improve the yield, but increased operating procedure, is not conducive to industrial production.

Currently, the key intermediate is patent protected, and z-type

Miyoshi butyric alcohol (compound 6) stereoselective low yield and

isolated intermediates, to solve this problem, to overcome technical

barriers to foreign pharmaceutical companies, urgent need to find a

simple process, low cost, easy to separate and viable for large-scale

production of synthetic routes.

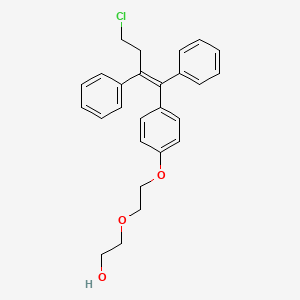

To achieve the above object, according to

one aspect of the present invention, there is provided a method of

synthesizing toremifene, synthetic method comprising: a step S1, so that

a compound having the structural formula II with a compound B having

the structural formula III C occurs Mike Murray to give compound D

having the structural formula IV; step S2, the Compound D and Compound E

or Compound E of the hydrochloride salt of the formula V having a

phenolic hydroxyl group on the occurrence of a selective alkylation

reaction, to give a compound having the structural formula VI F; step

S3, the compound F is reacted with thionyl chloride to give toremifene,

wherein,

Formula II is:

Structural formula III as follows:

Formula IV is

Of formula V is C1CH2CH2N (CH 3) 2; formula VI is

FIG. 1 illustrates the present invention obtained in Example 1 H NMR spectrum of compound D of implementation;

FIG. 2 shows the 1 H NMR spectrum of the present invention, the compound obtained in Example F;

FIG. 2 shows the 1 H NMR spectrum of the present invention, the compound obtained in Example F;

FIG. 3 shows the present invention is a proton nuclear magnetic resonance spectrum of toremifene obtained in Example.

FIG. 3 shows the present invention is a proton nuclear magnetic resonance spectrum of toremifene obtained in Example.

Figure 1, which shows a spectrum of results for Che bandit? (400 cm

take, 01 ^ 0) 3 = 9.20 (! 8,1 1), 7.37 (^ = 7.4 to take, 2 1!), 7.30- 7.

23 (m, 3H), 1.22- 7. 15 (m, 2H), 7. 15 – 7. 06 ( m, 3H), 6. 61 (dd, J =

9. 0, 2. 2Hz, 2H), 6. 49 -. 6. 32 (m, 2H), 4 48 (s, 1H), 3 30 (. m,

2H), 2 55 (t, J = 7. 5Hz, 2H);. F proton nuclear magnetic resonance

spectrum of the compound attached to the

Figure 2, showing spectrum results Che NMR (400MHz, DMSO) δ = 7. 36

(d, J = 7. 3Hz, 2H), 7. 31 – 7. 25 (m, 3H), 7. 21 – 7. 10 (m, 5H), 6. 75

– 6. 69 (m , 2H), 6. 59 (d, J = 8. 8Hz, 2H), 4. 49 (s, 1H), 3. 88 (t, J

= 5. 8Hz, 2H), 3. 31 (d, J = 4. 3Hz, 2H), 2. 57 (t, J = 7.5Hz, 2H),

2.52 (t, J = 4.6Hz, 2H), 2 15 (s, 6H);.

Tommy remifentanil NMR hydrogen spectrum in Figure 3 attached,

showing spectrum results Che NMR (400MHz, CDC13) δ = 7. 41 -. 7. 33 (m,

2H), 7 29 (dt, J = 7. 1, 2. 9Hz, 3H), 7. 20 (dd, J = 10. 0, 4. 3Hz, 2H),

7. 13 (dd, J = 7. 1, 4. 3Hz, 3H), 6.87- 6. 72 (m, 2H), 6. 57 (dd, J =

6. 8, 4. 8Hz, 2H), 3. 92 (t, J = 5. 8Hz, 2H), 3. 41 (t, J = 7. 5Hz, 2H),

2. 92 (t, J = 7. 5Hz, 2H), 2. 63 (t, J = 5. 8Hz, 2H), 2. 28 (s, 6H).

The synthetic routes above synthetic method are as follows:

Synthesis of toremifene:

To a 2L reaction flask 1. 1L of toluene,

110g (0. 28mol) obtained in the above step Z configuration compound F,

mixed to obtain a sixth system, the cooling system to the sixth mixed

0~5 ° C , was slowly added dropwise 99. 93g (0. 84mol) thionyl chloride

addition was complete the formation of the seventh mixed system, the

mixed system was slowly warmed to a seventh ll〇 ° C, for 1 hour to

obtain a third product system, stop The third product heating and

cooling system to 15~25 ° C, the third product system slowly poured into

1L of water, adding NaOH solution to a pH 9~10 and get the second

system, the second in and a system for liquid separation, and the

resulting aqueous phase to obtain a second solution was extracted with

1L toluene extraction, the organic phase of the second extraction

solution and liquid separation were combined and concentrated to give

crude toremifene, the crude product was mass ratio of 1 : mixed solvent

of ethyl acetate and acetone 1 crystals to give 103. 7g toremifene

products.

Synthesis of toremifene:

[0062] To a 5L reaction flask 3. 3L of

toluene, 110g (0. 28mol) obtained in the above step Z configuration

compound F, mixed to obtain a sixth system, the cooling system to the

sixth mixed 0~5 ° C , was slowly added dropwise 33. 31g (0. 28mol)

thionyl chloride addition was complete the formation of the seventh

mixed system, the mixed system was slowly warmed to a seventh ll〇 ° C,

after the reaction for 6 hours to obtain a third product system, stop

The third product heating and cooling system to 15~25 ° C, the third

product system slowly poured into 1L of water, potassium carbonate

solution to a pH 9~10 and get the second system, the second and system

for liquid separation, and the resulting aqueous phase to obtain a

second solution was extracted with 1L ethyl acetate, the organic phase

after the second extraction solution and liquid separation were combined

and concentrated to give crude toremifene, the crude product was

quality ratio was crystallized from acetone to give 92. 2g toremifene

products.

Purity of toremifene following method:

[0107] to take the product, add the mobile

phase dissolved and diluted into 1ml of 1. Omg solution containing,

according to HPLC octadecylsilane bonded silica as a filler to square 1%

trifluoroacetic acetic acid aqueous solution (A) and acetonitrile (B)

as the mobile phase gradient elution (T = Omin 10% B; T = lOmin 95% B; T

= 12min 100% B; T = 15min 10% B), detection wavelength 210nm; area

normalization method to calculate the Z configuration purity compound F,

where F Z configuration compound retention time of 6. 76min. The

purity of the above calculation or Z configuration detection obtained

compound D, compound D Z configuration and E configuration of the weight

ratio, toremifene yield and purity are reported in Table 1 below.

……………..

PATENT

http://www.google.com/patents/US5491173

c) 4-chloro-1,2-diphenyl-1-[4-[2-(N ,N-dimethylamino)ethoxy]phenyl]-1-butene (Z and E)

(Z)-isomer: The reaction is performed under dry conditions. 42.4 g of

(Z)-1,2-diphenyl-1-[4-[2-(N,N-dimethylamino

)ethoxy]phenyl]-1-buten-4-ol are dissolved in 250 ml of chloroform. Then

23.8 g of thionyl chloride areadded dropwise. The mixture is refluxed 3

h. The solvent is evaporated, after which the product is recrystallized

from ethyl acetate. The yield ofthe hydrochloride salt is 36.7 g (83%),

m.p. 194°-6° C. The base can be liberated from the Salt with 1M sodium

carbonate solution, after which the base is extracted in toluene. The

toluene solution is dried and the solvent is evaporated. The free base

has m.p. 108°-10° C. (from acetone).

1 H-NMR-spectrum (CDCl

3): δ 2.27 (6H, s), 2.63

(2H, t), 2.91 (2H, t), 3.41 (2H, t), 3.92 (2H, t), 6.54 (2H, d), 6.79

(2H. d), 7.15(5H, s), 7.31 (5H, s). MS: m/z 405/407 (M

+, 7/3), 72 (20), 58 (100).

The citric acid salt can be prepared as follows: 40.6 g of the

(Z)-isomer as a free base are dissolved in 175 ml of warm acetone and

24.3 g of citric acid are dissolved in 100 ml of warm acetone. The

solutions are combined and the mixture is allowed to cool. The citrate,

m.p. 160°-162° C., is collected by filtration.

(E)-isomer: The compound is prepared from (E)-1,2-diphenyl-1-[4-[2-(N

,N-dimethylamino)ethoxy]phenyl]-1-buten-4-ol in the same manner as the

corresponding (Z)-isomer. The hydrochloride salt is crystallized from

toluene. The yield is 35.8 g (81%) of a product having m.p. 183°-5° C.

The base can be liberated from the salt in the same manner as the

corresponding (Z)-isomer. It has m.p. 69°-71° C. (from hexane).

1 H-NMR-spectrum (CDCl

3): b 2.34 (6H, s), 2.74 (2H, t), 2.97 (2H,t), 3.43 (2H, t), 4.08 (2H, t), 6.80-7.30 (14H, m).

MS: m/z 405/407 (M

+, 7/3) 72 (19) 58 (100)

EXAMPLE 4

4-chloro-1,2-diphenyl-1-[4-[2-(N ,N-diethylamino)ethoxy]phenyl ]-1-butene (Z and E)

43.3 g of

1,2-diphenyl-1-[4-[2-(N,N-diethylamino)ethoxy]phenyl]butane-1,4-diol

(pureenantiomer pairs or their mixture: m.p. of (RR,SS)-pair is 107°-9°

C.)is suspended in 250 ml of toluene, after which 25ml toluene is

distilled off to dry the solution. The mixture is cooled to 0° C. with

stirring. While stirring and keeping the temperature at 0° C. or a

little below, 47.6 g of thionyl chloride of good qualityare added. The

mixture is stirred for 1 h at 0° C. and the temperature is then allowed

to rise to 22° C. The mixture is stirred at 80° C. until the reaction is

completed (about 3 h). After that, water is added to decompose the

excess of thionyl chloride followed by 20% sodium hydroxide solution to

liberate the product from itshydrochloride salt. The aqueous layer is

discarded and the toluene layer iswashed with water. Then the solvent is

evaporated to leave a mixture of (Z)- and (E)isomers (Z:E 7:3) as an

oil in quantitative yield.

(Z)-isomer: The (Z)-isomer is isolated from the isomer mixture above

as thehydrochloride salt because of the low melting point of the free

base. The m.p. of the hydrochloride salt is 178°-80° C. The

(Z)-isomermay be freed from its salt by any normal method.

1 H-NMR-spectrum (CDCl

3): δ 1.01 (6H, t), 2.57

(4H, q), 2.77 (2H, t), 2.91 t), 3.41 (2H, t), 3.90 t), 6.53 (2H, d),

6.78 (2H, d), 7.15 (5H, s), 7.31 (5H, s). (E)-isomer:

1 H-NMR-spectrum (CDCl

3): δ 1.07 (6H, t), 2.66 (4H, q), 2.89 (2H, t), 2.97 (2H, t), 3.42 (2H, t), 4.07 (2H, t), 6.90-7.20 (10H, m).

……………….

SEE

http://www.google.co.ug/patents/EP0095875B1?cl=en

………….

http://www.intechopen.com/books/topics-on-drug-metabolism/electrochemical-methods-for-the-in-vitro-assessment-of-drug-metabolism

References

- Price N, Sartor O,

Hutson T, Mariani S. Role of 5a-reductase inhibitors and selective

estrogen receptor modulators as potential chemopreventive agents for

prostate cancer. Clin Prostate Cancer 2005;3:211-4. PMID 15882476

- “GTx’s Phase III Clinical Development of ACAPODENE on Course Following Planned Safety Review” (Press release). GTx Inc. 2007-07-12. Retrieved 2006-07-14.

- “GTx Announces Toremifene 80 mg NDA Accepted for Review by FDA” (Press release).

- “GTx and Ipsen End Prostate Cancer Collaboration due to Costs of FDA-Requested Phase III Study”. 2 Mar 2011

///////

LIONEL MY SON

LIONEL MY SON