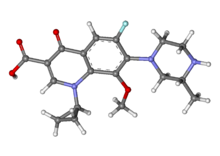

GATIFLOXACIN

BMS-206584, CG-5501, AM-1155, Zymar, Bonoq, Gatiflo, AM-1155

(±)-1-Cyclopropyl-6-fluoro-8-methoxy-7-(3-methyl-1-piperazinyl)-4-oxo-1,4-dihydroquinoline-3-carboxylic acid

Originally developed at Kyorin, gatifloxacin was first licensed to

Gruenenthal in Europe, and that company still maintains rights to the

oral and injectable formulations of the product. In October 1996, Kyorin

licensed gatifloxacin to BMS, granting the company development and

marketing rights in the U.S., Canada, Australia, Mexico, Brazil and

certain other markets. In 2006, rights to the compound were returned by

BMS. Subsequently, Senju and Kyorin signed a licensing agreement

regarding the development of ethical eye drops containing the

fluoroquinolone. In April 2000, Sumitomo Dainippon Pharma agreed to

comarket the oral formulation in Japan. In August of that year, Allergan

in-licensed gatifloxacin from Kyorin, gaining development and

commercialization rights to the drug in all territories except Japan,

Korea, China and Taiwan. The India-based Lupin Pharmaceuticals signed an

agreement in June 2004 with Allergan to promote the ophthalmic solution

of gatifloxacin in the pediatric specialty area in the U.S. PediaMed

Pharmaceuticals also holds rights to the drug. In 2009, Kyorin licensed

the drug candidate to Senju in China.

Gatifloxacin is the common name for

(±)-1-cyclopropyl-6-fluoro-1,4-dihydro-8-methoxy-7-(3-methyl-1-piperazinyl)-4-oxo-3-quinolinecarboxylic

acid (1), one of the most important broad-spectrum antibacterial

agents and a member of the fourth-generation fluoroquinolone

family.(1)Fluoroquinolones inhibit the enzyme DNA gyrase (topoisomerase

II), which is responsible for the supercoiling of the DNA double helix,

preventing the replication and repair of bacterial DNA and

RNA.(2) Gatifloxacin (1) reached the market in 1999 under the

brand name Tequin for the treatment of respiratory tract infections. The

drug is available as tablets and aqueous solutions for intravenous

therapy as well as eye drop formulation (Zymar).

To date, there are several processes described for the preparation

of gatifloxacin, which can be grouped into two main categories: direct

substitution of the 7-position fluorine atom of

1-cyclopropyl-6,7-difluoro-1,4-dihydro-8-methoxy-4-oxo-3-quinolinecarboxylic

acid (2) by 2-methylpiperazine (Scheme 1),(3-5) and through

boron chelate-type intermediates to overcome the diminished reactivity

induced by the 8-methoxy group, which uses as starting material the

ethyl ester derivative 3 (Scheme 2).(6-9)

SCHEME1

- 1.

Mather, R.; Karenchak, L. M.; Romanowski, E. G.; Kowalski, R. P. Am. J. Ophthalmol.2002, 133 ( 4) 463

- 2.

Corey, E. J.; Czakó, B.; Kürti, L. Molecules and Medicine; Wiley: NJ, 2007; p 135.

- 3.

Masuzawa, K.; Suzue, S.; Hirai, K.; Ishizaki, T. 8-Alkoxyquinolonecarboxylic

acid and salts thereof excellent in the selective toxicity and process

of preparing the same EP 0 230 295 A3, 1987.

- 4.

Niddam-Hildesheim, V.; Dolitzky, B.-Z.; Pilarsky, G.; Steribaum, G. Synthesis of Gatifloxacin WO 2004/069825 A1, 2004.

- 5.

Ruzic, M; Relic, M; Tomsic, Z; Mirtek, M. Process for the

preparation of Gatifloxacin and regeneration of degradation products WO

2006/004561 A1, 2006.

- 6.

Iwata, M.; Kimura, T.; Fujiwara, Y.; Katsube, T. Quinoline-3-carboxylic

acid derivatives, their preparation and use EP 0 241 206 A2, 1987.

- 7.

Sanchez, J. P.; Gogliotti, R. D.; Domagala, J. M.;

Garcheck, S. J.; Huband, M. D.; Sesnie,J. A.; Cohen, M. A.; Shapiro, M.

A. J. Med. Chem. 1995, 38, 4478

- 8.

Satyanarayana, C.; Ramanjaneyulu, G. S.; Kumar, I. V. S. Novel crystalline forms of Gatifloxacin WO 2005/009970 A1 2005.

- 9.

Takagi, N.; Fubasami, H.; Matsukobo, H.; (6,7-Substituted-8-alkoxy-1-cyclopropyl-1,4-dihydro-4-oxo-3-quinolinecarboxylic acid-O3,O4)bis(acyloxy-O)borates and the salts thereof, and methods for their manufacture EP 0 464 823 A1, 1991.

………………………….

WO 2005009970

http://www.google.com/patents/WO2005009970A1?cl=en

preparation of Gatifloxacin hemihydrate from Ethyl-1- Cyclopropyl-6,

7-difluoro-8-methoxy-4-oxo-l, 4-dihydro-3-quinoline carboxylate through

boron difluoride chelate. Ethyl-1-cyclopropyl- 6,

7-difluoro-8-methoxy-4-oxo-l, 4-dihydro-3-quinoline carboxylate is

reacted with aqueous hydrofluoroboric acid followed by condensation with

2-methyl piperazine in polar organic solvent resulting in an

intermediate l-Cyclopropyl-7- (3-methyl piperazin-1- yl).

-6-fluoro-8-methoxy-4-oxo-l, 4-dihydro-3-quinoline carboxylic acid boron

difluoride chelate. This intermediate may be further hydrolyzed to

yield Gatifloxacin. Gatifloxacin so obtained may needs purification to

yield high purity product. However to obtain directly high purity

Gatifloxacin it is desirable to isolate the intermediate by cooling to

low temperatures . Treating with an alcohol or mixture of alcohols

purifies this intermediate. The purified condensed chelate in aqueous

ethanol on hydrolysis with triethylamine followed by crystallization in

ethanol gives Gatifloxacin hemihydrate with high purity.

STAGE – I:

Ethyl l-cyclopropyl-6,7-difluoro-8-met oxy l-Cycloproρyl-6,

7-difluoro-8-methoxy -4-oxo-l, -dihydro-3-quinoline -4-oxo-l,

4-dihydro-3-quinoline carboxylate carboxylic acid boron difluoride

chelate

STAGE – II :

l-Cycloprop l-7- ( 3-methylpiperazin-l-yl.

6-fluoro~8-methoxy-4-oxo-l , 4-dihydro-3- carboxylicacid

borondifluoride chelate quinoline carboxylicacid borondifluoride chelate

STAGE -III :

l-Cyclopropyl-7- (3- ethylpiperaz.in-l-yl . GATIFLOXACIN

-6-fluoro-8-methoxy-4-oxo-l , 4-dihydro-3- quinoline carboxylicacid borondifluoride chelate

Example-I: Preparation of Gatifloxacin • with isolation of intermediate (boron difluoride chelate derivative)

Stage-1: Preparation of l-cyclopropyl-6, 7-di luoro-8-methoxy-4-oxo-

1, 4-dihydro-3-quinoline carboxylic acid boron difluoride chelate.

Ethyl-l-cyclopropyl-6, 7-difluoro-8-methoxy-4-oxo-l, -dihydro-3-

quinόline carboxylate (100g)is suspended in ,40%aq..hydrofluoroboric

acid -(1000 ml). Temperature of • the reaction mass is raised and

maintained at 95°C to 100°C for 5hrs followed by cooling to 30°C – 35°C.

Water (400 ml) is added and maintained at 25°C – 30°C for 2hrs .

Product is filtered, washed with water (500 ml) and dried at 40°C – 45°C

to constant weight. Dry weight of the product: 101.6 g (Yield: 95.8 %)

Stage-2: Preparation of 1- Cyclopropyl-7- (3-methylpiperazin-l-yl) –

6-fluoro-8-methoxy-4-oxo-l, -dihydro-3-quinoline carboxylic acid boron

difluoride chelate

100 g of Boron difluoride chelate derivative prepared as above in

stage-1 is suspended in acetonitrile (800 ml) , to that 2-methyl

piperazine (44.0 g, 1.5 mole equiv.) is added and mixed for 15 min to

obtain a clear solution. The reaction mass is maintained at 30°C – 35°C

for 12 hrs followed by cooling to -10°C to -5°C. The reaction mass is

maintained at -10°C to -5°C for 1 hr. The product is filtered and dried

at 45°C – 50°C to constant weight. Dry weight of the product: 116.0 g

(Yield: 93.9 %) .

The condensed chelate (100 g) prepared as above is suspended in

methanol (1500 ml), maintained at 40°C – 45°C for 30 min. The reaction

mass is gradually cooled, maintained for 1 hr at -5°C to 0°C. The

product is filtered, washed with methanol (50 ml) and dried at 45°C –

50°C to constant weight. Dry weight of the product: 80.0 g (Yield: 80.0

%)

Stage -3: Preparation of Gatifloxacin (Crude)

The pure condensed chelate (100.0 g) prepared as above in stage-2 is

suspended in 20% aq. ethanol (1000 ml) , the temperature is raised and

maintained at 75°C to 80°C for 2 hrs. The reaction mass is cooled,

filtered to remove insolubles, distilled under vacuum to remove solvent.

Fresh ethanol (200 ml) is added and solvent is removed under vacuum at

temperature below 50°C. Ethanol (200 ml) is added to the residue and

gradually cooled to -10°C to -5°C. The reaction mass is mixed at -10°C

to -5°C for 1 hr and then filtered. The wet cake is washed with ethanol

(25 ml) and dried at 45°C – 50°C to constant weight.

The dry weight of the Gatifloxacin is 83.3 g (Yield: 91.7 %)

Stage- 4: Purification of crude Gatifloxacin

Crude Gatifloxacin (100.0 g) prepared as above in stage-3 is

suspended in methanol (4000 ml), the temperature is raised and

maintained at 60°C to 65°C for 20 min. to get a clear solution.

Activated carbon (5 g) is added, maintained for 30 min and the solution

is filtered. The filtrate is concentrated to one third of its original

volume under vacuum at temperature below 40°C. The reaction mass is

gradually cooled and maintained at -10°C to -5°C for 2 hrs. The product

is filtered, washed with methanol (50 ml) and dried at 45°C – 50°C to

constant weight. The dry weight of the pure Gatifloxacin is 76.0 g

(Yield: 76.0 %)

Example-II: Preparation of Gatifloxacin without isolation of intermediate (boron difluoride chelate derivative)

Stage-1: Preparation of l-cyclopropyl-6, 7-difluoro-8-methoxy-4-

oxo-1, 4-dihydro-3-quinoline carboxylic acid boron difluoride chelate.

Ethyll-cyclopropyl-6, 7-difluoro-8-methoxy-4-oxo-l, 4-dihydro-3-

quinoline carboxylate (lOOg) is suspended in 40% aq. hydrofluoroboric

acid (1000 ml) . Temperature of the reaction mass is raised and

maintained at 95°C to 100°C for 5 hrs followed by cooling to 30°C –

35°C. 400 ml DM water is added, maintained at 25°C – 30°C for 2hrs . The

product is filtered, washed with DM water (500 ml) and dried at 40°C –

45°C to constant weight. The dry wt is 102.5 g (Yield: 96.6 %)

Stage – 2: Preparation of Gatifloxacin (Crude)

The boron difluoride chelate derivative (100 g) prepared as above in

stage-1 is suspended in acetonitrile (800 ml) , 2-methyl piperazine (44

g, 1.5 mole equiv.) is added and mixed for 15 min to obtain a clear

solution. The reaction mass is maintained at 30°C – 35°C for 12 hrs.

Removed the solvent by vacuum distillation. 20% Aq. ethanol (1000 ml) is

added, raised the temperature and maintained at 75°C to 80°C for 2 hrs.

The reaction mass is cooled, filtered to remove insolubles. The

filtrate is distilled under vacuum to remove solvent completely. Fresh

ethanol (250 ml) is added and distilled under vacuum at temperature

below 50°C. Fresh Ethanol (250 ml) is added to the residue and gradually

cooled to -10°C to -5°C. The reaction mass is maintained at -10°C to

-5°C for 1 hr and filtered. The wet cake is washed with ethanol (30 ml)

and dried at 45°C – 50°C to constant weight.

The dry weight of the Gatifloxacin is 73.5 g (Yield: 65.4 %)

Stage -3: Purification of crude Gatifloxacin

Crude Gatifloxacin (80.0 g) prepared as above in stage-2 is suspended

in methanol (2000 ml) , the temperature is raised and maintained at

60°C to 65°C for 20 min. to get a clear solution. The reaction mixture

is filtered. The filtrate is gradually cooled and maintained at -10°C to

-5°C for 2 hrs. The product is filtered, washed with methanol (50 ml)

and dried at 45°C – 50°C to constant weight.

The dry weight of the pure Gatifloxacin is 56.0 g (Yield: 70.0 %)

……………………….

WO 2005047260

http://www.google.co.in/patents/WO2005047260A1?cl=en

Gatifloxacin is the international common name of

l-cyclopropyl-6-fluoro-l, 4-dihydro-8-methoxy- 1-

(3-methyl-l-piperazinyl) -4-oxo-3-guinolin-carboxylic acid of formula

(I) , with application in medicine and known for its antibiotic

activity:

European patent application EP-A-230295 discloses a process for

obtaining gatifloxacin that consists on the reaction of compound (II)

with 2-

In this process the gatifloxacin is isolated in the form of a

hemihydrate after a laborious process of column chromatography and

recrystallisation in methanol, which contributes towards making the

final yield lower than 20% by weight. Moreover, in said process an

undesired by-product is formed, resulting from demethylation at position

8 of the ring. European patent application EP-A-241206 discloses a

process for preparing gatifloxacin, whose final steps are as follows:

(III) H ft N Me H DMSO

Gatifloxacin (I)

(IV) This process uses the intermediate compound (III) , which has

been prepared and isolated in a separate operation, while the

intermediate compound (IV) is also isolated before proceeding to its

conversion into gatifloxacin by treatment with ethanol in the presence

of triethylamine. The overall yield from these three steps is lower than

40%. These disadvantages — a synthesis involving several steps, low

yields, and the need to isolate the intermediate products — hinder the

production of gatifloxacin on an industrial scale. There is therefore a

need to provide a process for preparing gatifloxacin with a good

chemical yield, without the need to isolate the intermediate compounds

and that substantially avoids demethylation in position 8 of the ring.

The processes termed in English “one pot” are characterised in that the

synthesis is carried out in the same reaction vessel, without isolating

the intermediate compounds, and by means of successive addition of the

reacting compounds. The authors of the present invention have discovered

a simplified process for preparing gatifloxacin which does not require

isolation of the intermediate compounds .

Example 1: Preparing gatifloxacin from compound (II) 10 g (0.0339 moles, 1 equivalent) of compound

(II) is placed in a flask, 30 ml of acetonitryl (3 volumes) is added and this is heated to a temperature of 76-80° C.

Once reflux has been attained, and being the temperature maintained,

3.28 g (0.0203 moles, 0.6 equivalents) of hexamethyldisilazane (HMDS) is

added with a compensated adding funnel. Once addition is completed, the

reaction is maintained with stirring for 1 hour at a temperature of

76-80° C. Once this period has elapsed, the reaction mixture is cooled

to a temperature ranging between 0 and 15° C, and 5.78 g (0.0407 moles,

1.2 equivalents) of boron trifluoride ethyletherate is added while

keeping the temperature below 15° C. Once addition is completed, the

temperature is allowed to rise to 15- 25° C and it is kept under these

conditions for approximately 2 hours. The pH of the mixture is then

adjusted to an approximate value of 9 with triethylamine (approximately 2

ml) . To the resulting suspension is added a solution of 10.19 g

(0.1017 moles, 3 equivalents) of 2-methylpiperazine in 28 ml of

acetonitryl, while maintaining the temperature between 15 and 25° C. The

resulting amber solution is kept with stirring under these conditions

for approximately 3 hours . Once the reaction has been completed, the

solution is distilled at low pressure until a stirrable paste is

obtained. At this point 50 ml of methanol is added, the resulting

suspension is raised to a temperature of 63-67° C and is kept under

these conditions for approximately 5 hours . Once the reaction has been

completed, the mixture is cooled to a temperature of 25-35° C in a water

bath, and then at a temperature of 0-5° C in a water/ice bath for a

further 1 hour. The resulting precipitate is filtered, washed with cold

methanol (2 x 10 ml) and dried at 40° C in a vacuum oven to constant

weight. 10.70 g of crude gatifloxacin is obtained, having a water

content of 2.95% by weight. The yield of the process is 81.8%.

The crude product is crystallised in methanol by dissolving 20 g of

crude gatifloxacin in 1 1 of methanol (50 volumes) at a temperature of

63-67° C. Once all the product has been dissolved, the solution is left

to cool to a temperature of 30-40° C, and then to a temperature of 0-5° C

in a water/ice bath, maintaining it under these conditions for 1 hour.

The resulting suspension is filtered and the solid retained is washed

with 20 ml (1 volume) of cold methanol. The solid obtained is dried at

40° C in a vacuum oven to provide 18.65 g of gatifloxacin with a water

content of 2.36% by weight.

The overall yield from the compound (II) is 77.7%, with a purity

exceeding 99.8% as determined by HPLC chromatography. The content of

by-product resulting from demethylation in position 8 of the ring is

lower than 0.1% as determined by HPLC chromatography.

PAPER

) through use of

boron chelate intermediates has been developed. The methodology involves

an initial activation step which accelerates the formation of the first

chelate under low-temperature conditions and prevents demethylation of

the starting material. To increase the overall yield and to avoid the

isolation and manipulation of the resulting intermediates, the process

has been designed to be carried out in one pot. As a result, we present

here an easy, scaleable and substantially impurity-free process to

obtain gatifloxacin (

) in high yield.

Department of Research & Development, Química Sintética S.A.,

c/ Dulcinea s/n, 28805 Alcalá de Henares, and Department of Organic

Chemistry, University of Alcalá, 28871 Madrid, Alcalá de Henares, Spain

Org. Process Res. Dev., 2008, 12 (5), pp 900–903

DOI: 10.1021/op800042a

18

DSC analysis showed two endothermic peaks at 166.2 °C (T onset = 164.3 °C) and 190.0 °C (T onset

= 188.2 °C) and an exothermic one at 168.1 °C. The shape of this DSC

curve is characteristic of a monotropic transition between crystalline

forms

Water content by Karl Fischer 3.0%

(19) MS

m/

z 376 (M+ + H);

19

Although there are several hydrates described for gatifloxacin such

as, among others, the hemimydrate, sesquihydrate, and pentahydrate(Raghavan, K.

S.; Ranadive, S. A.;Gougoutas, J. Z.; Dimarco, J. D.; Parker, W.

L.; Dovich, M.; Neuman, A.Gatifloxacin pentahydrate. WO 2002/22126

A1, 2002) , the Gatifloxacin obtained by the present procedure does not

seem to form a stoichometric hydrate, but instead it retains moisture.

Thus, the product is usually

obtained with a Karl-Fischer value below 1% after drying, but it can

absorb moisture until a final content of about 3%. This water content

can vary between 2.0% and 3.5%, depending on the relative humidity of

the environment. DSC analysis revealed a broad endothermic signal with

minimum at 76 °C, while TGA analysis showed that the product loses all

the water below 80 °C.

No loss of weight is registered when

the product melts, and the weight is constant until the decomposition

of the material at about 200 °C. On the basis of these results, it can

be said that the water content of the gatifloxacin obtained by the

present process is retained moisture instead of water belonging to the

lattice. The shape of the derivative of the weight curve at the

beginning of the analysis shows that the sample has already lost part of

the moisture when the register starts. This is probably due to the

sample starting to lose weight when makes contact with the dry

atmosphere of the TGA oven that could explain the different values

obtained for water content of the analyzed sample by TGA (1.90%) and

Karl-Fischer (2.64%) methods.

1H NMR (DMSO-d6) δ 0.97 (d, J = 6.1 Hz, 3H), 1.04 (m, 2H), 1.15 (m, 2H), 2.75−2.94 (m, 4H) 3.14 (m, 1H), 3.30 (m, 2H), 3.74 (s, 3H), 4.15 (m, 1H), 7.70 (d, JH−F = 12.2 Hz, 1H), 8.67 (s, 1H).

13C NMR (DMSO-d6) δ 8.40, 8.42, 18.66, 40.28, 45.46, 50.17, 50.29 (d, JC−F = 3.44 Hz), 57.36 (d, JC−F = 3.74 Hz), 62.15, 106.0 (d, JC−F = 22.7 Hz), 106.04, 120.05 (d, JC−F = 8.6 Hz), 133.6 (d, JC−F = 1.1 Hz), 138.9 (d, JC−F = 11.9 Hz), 145.2 (d, JC−F = 5.87 Hz), 149.88, 155.06 (d, JC−F = 249.2 Hz), 165.56, 175.56 (d, JC−F = 3.3 Hz).

19F NMR (DMSO-d6) δ −120.4 (d, J = 12.2 Hz).

Anal. Calcd for C19H22N3O4F + 3.0% H2O; C, 58.95; H, 6.07; N, 10.85. Found: C, 58.90; H, 5.82; N, 10.90.

Side-effects and removal from the market

A

Canadian study published in the

New England Journal of Medicine in March 2006 claims Tequin can have significant

side effectsincluding

dysglycemia.

[2] An

editorial by Dr. Jerry Gurwitz in the same issue called for the

Food and Drug Administration (FDA) to consider giving Tequin a

black box warning.

[3] This

editorial followed distribution of a letter dated February 15 by

Bristol-Myers Squibb to health care providers indicating action taken

with the FDA to strengthen warnings for the medication.

[4] Subsequently

it was reported on May 1, 2006 that Bristol-Myers Squibb would stop

manufacture of Tequin, end sales of the drug after existing stockpiles

were exhausted, and return all rights to Kyorin.

[5]

Union Health and Family Welfare Ministry of India on 18 March 2011

banned the manufacture, sale and distribution of Gatifloxacin as it

caused certain adverse side effects

[6]

Contraindications

Diabetes[7]

Availability

Gatifloxacin is currently available only in the US and Canada as an ophthalmic solution.

In China it is sold in tablet as well as in eye drop formulations.

Ophthalmic anti-infectives are generally well tolerated. The

concentration of the drug observed following oral administration of

400 mg gatifloxacin systemically is approximately 800 times higher than

that of the 0.5% Gatifloxacin eye drop. Given as an eye drop,

Gatifloxacin Ophthalmic Solution 0.3% & 0.5% cause very low systemic

exposures. Therefore, the systemic exposures resulting from the

gatifloxacin ophthalmic solution are not likely to pose any risk for

systemic toxicities.

- The reaction of 1-bromo-2,4,5-trifluoro-3-methoxybenzene (I) with

CuCN and N-methyl-2-pyrrolidone at 150 C gives

2,4,5-trifluoro-3-methoxybenzonitrile (II), which by treatment with

concentrated H2SO4 yields the benzamide (III) The hydrolysis of (III)

with H2SO4 -. water at 110 C affords 2,4,5-trifluoro-2-methoxybenzoic

acid (IV), which by reaction with SOCl2 is converted into the acyl

chloride (V). The condensation of (V) with diethyl malonate by means of

magnesium ethoxide in toluene affords diethyl 2-

(2,4,5-trifluoro-3-methoxybenzoyl) malonate (VI), which by treatment

with p-toluenesulfonic acid in refluxing water gives ethyl 2-

(2,4,5-trifluoro-3-methoxybenzoyl) acetate (VII). The condensation of

(VII) with triethyl orthoformate in refluxing acetic anhydride yields

3-ethoxy -2- (2,4,5-trifluoro-3-methoxybenzoyl) acrylic acid ethyl ester

(VIII), which is treated with cyclopropylamine (IX) to afford the

corresponding cyclopropylamino derivative (X). The cyclization of (X) by

means of NaF in refluxing DMF gives

1-cyclopropyl-6,7-difluoro-8-methoxy-4-oxo-1,4-dihydroquinoline-3-carboxylic

acid ethyl ester (XI), which is hydrolyzed with H2SO4 in acetic acid to

yield the corresponding free acid (XII). Finally, this compound is

condensed with 2-methylpiperazine (XIII) in hot DMSO.

|

|

Title: Gatifloxacin

CAS Registry Number: 112811-59-3

CAS Name: 1-Cyclopropyl-6-fluoro-1,4-dihydro-8-methoxy-7-(3-methyl-1-piperazinyl)-4-oxo-3-quinolinecarboxylic acid

Trademarks: Tequin (BMS); Zymar (Allergan)

Molecular Formula: C19H22FN3O4

Molecular Weight: 375.39

Percent Composition: C 60.79%, H 5.91%, F 5.06%, N 11.19%, O 17.05%

Literature References: Fluorinated quinolone antibacterial. Prepn: K. Masuzawa et al., EP 230295; eidem, US 4980470 (1987, 1990 both to Kyorin); J. P. Sanchez et al., J. Med. Chem. 38, 4478 (1995); of the sesquihydrate: T. Matsumoto et al., US5880283 (1999 to Kyorin). In vitro antibacterial activity: A. Bauernfeind, J. Antimicrob. Chemother. 40, 639 (1997); H. Fukuda et al., Antimicrob. Agents Chemother. 42, 1917 (1998). Clinical pharmacokinetics: M. Nakashima et al., ibid. 39, 2635 (1995). Clinical study in urinary tract infection: H. Nito, 10th Mediterranean Congr. Chemother. 1996, 327; in respiratory tract infection: S. Sethi, Expert Opin. Pharmacother. 4, 1847 (2003).

Properties: Pale yellow prisms from methanol as hemihydrate, mp 162°.

Melting point: mp 162°

Derivative Type: Sesquihydrate

CAS Registry Number: 180200-66-2

Manufacturers’ Codes: AM-1155

Molecular Formula: C19H22FN3O4.1½H2O

Molecular Weight: 384.40

Percent Composition: C 59.37%, H 6.03%, F 4.94%, N 10.93%, O 18.73%

Therap-Cat: Antibacterial.

Keywords: Antibacterial (Synthetic); Quinolones and Analogs

|

References

- Burka JM, Bower KS, Vanroekel RC, Stutzman RD, Kuzmowych CP, Howard RS (July 2005). “The

effect of fourth-generation fluoroquinolones gatifloxacin and

moxifloxacin on epithelial healing following photorefractive

keratectomy”. Am. J. Ophthalmol. 140 (1): 83–7. doi:10.1016/j.ajo.2005.02.037.PMID 15953577.

- Park-Wyllie, Laura Y.; David N. Juurlink;

Alexander Kopp; Baiju R. Shah; Therese A. Stukel; Carmine Stumpo; Linda

Dresser; Donald E. Low; Muhammad M. Mamdani (March 2006).“Outpatient Gatifloxacin Therapy and Dysglycemia in Older Adults”. The New England Journal of Medicine 354 (13): 1352–1361. doi:10.1056/NEJMoa055191. PMID 16510739. Retrieved 2006-05-01. Note: publication date 30 March; available on-line 1 March

- Gurwitz, Jerry H. (March 2006). “Serious Adverse Drug Effects — Seeing the Trees through the Forest”. The New England Journal of Medicine 354 (13): 1413–1415.doi:10.1056/NEJMe068051. PMID 16510740. Retrieved2006-05-01.

- Lewis-Hall, Freda (February 15, 2006). “Dear Healthcare Provider:” (PDF). Bristol-Myers Squibb. Retrieved May 1, 2006.

- Schmid, Randolph E. (May 1, 2006). “Drug Company Taking Tequin Off Market”. Associated Press. Archived from the original on November 25, 2007. Retrieved 2006-05-01.[dead link]

- “Two drugs banned”. The Hindu (Chennai, India). 19 March 2011.

- Peggy Peck (2 May 2006). “Bristol-Myers Squibb Hangs No Sale Sign on Tequin”. Med Page Today. Retrieved 24 February2009.

| EP0610958A2 * |

20 Jul 1989 |

17 Aug 1994 |

Ube Industries, Ltd. |

Intermediates in the preparation of 4-oxoquinoline-3-carboxylic acid derivatives |

| ES2077490A1 * |

|

|

|

Title not available |

| Citing Patent |

Filing date |

Publication date |

Applicant |

Title |

| WO2008126384A1 |

31 Mar 2008 |

23 Oct 2008 |

Daiichi Sankyo Co Ltd |

Method for producing quinolone carboxylic acid derivative |

| CN101659654B |

28 Aug 2008 |

6 Nov 2013 |

四川科伦药物研究有限公司 |

2-Methylpiperazine fluoroquinolone compound and preparation method and application thereof |

| CN102351843A * |

18 Aug 2011 |

15 Feb 2012 |

张家口市格瑞高新技术有限公司 |

Synthesis method of 2-methyl piperazine lomefloxacin |

| EP1832587A1 * |

2 Mar 2007 |

12 Sep 2007 |

Quimica Sintetica, S.A. |

Method for preparing moxifloxacin and moxifloxacin hydrochloride |

| US7365201 |

2 Mar 2006 |

29 Apr 2008 |

Apotex Pharmachem Inc. |

Process for the preparation of the boron difluoride chelate of quinolone-3-carboxylic acid |

| US7875722 |

30 Sep 2009 |

25 Jan 2011 |

Daiichi Sankyo Company, Limited |

Method for producing quinolone carboxylic acid derivative |

| EP0464823A1 * |

Jul 4, 1991 |

Jan 8, 1992 |

Kyorin Pharmaceutical Co., Ltd. |

(6,7-Substituted-8-alkoxy-1-cyclopropyl-1,4-dihydro-4-oxo-3-quinolinecarboxylic

acid-O3,O4)bis(acyloxy-O)borates and the salts thereof, and methods for

their manufacture |

| US4997943 * |

Mar 31, 1987 |

Mar 5, 1991 |

Sankyo Company Limited |

Quinoline-3-carboxylic acid derivatives |

| Citing Patent |

Filing date |

Publication date |

Applicant |

Title |

| CN101659654B |

Aug 28, 2008 |

Nov 6, 2013 |

四川科伦药物研究有限公司 |

2-Methylpiperazine fluoroquinolone compound and preparation method and application thereof |

| CN102351843A * |

Aug 18, 2011 |

Feb 15, 2012 |

张家口市格瑞高新技术有限公司 |

Synthesis method of 2-methyl piperazine lomefloxacin |

* Cited by examiner

TAKE A TOUR

TAKE A TOUR

Amritsar, punjab, India

-

Amritsar is one of the largest cities of the Punjab state in India.

The city origin lies in the village of Tung, and was named after the

lake founded by the fourth Sikh …

GOLDEN TEMPLE

.

Tandoori chicken at Surjit Food Plaza. amritsar

The Jallianwalla Bagh in 1919, months after the massacre

Mealtime at the Golden Temple Amritsar

Golden Temple – Harmandir Sahib: Free food for everyone

-

-

Maharaja Ranjit Singh’s Ram Bagh Gardens

-

-

-

-

-

-

-

-

-

-

///////////

.

.