Nizatidine is a histamine

H2 receptor antagonist that inhibits

stomach acid production, and is commonly used in the treatment of

peptic ulcer disease and

gastroesophageal reflux disease. It was developed by

Eli Lilly and is marketed under the brand names

Tazac and

Axid.

Clinical use

Main article:

H2 antagonist

Nizatidine is used to treat

duodenal ulcers,

gastric ulcers, and

gastroesophageal reflux disease (GERD/GORD), and to prevent

stress ulcers.

[1]

Adverse effects

Side effects are uncommon, usually minor, and include diarrhea, constipation, fatigue, drowsiness, headache, and muscle aches.

[1]

History and development

Nizatidine was developed by

Eli Lilly, and was first marketed in 1987. It is considered to be equipotent with

ranitidine and differs by the substitution of a

thiazole ring in place of the

furan ring in ranitidine. In September 2000, Eli Lilly announced they would sell the sales and marketing rights for Axid to

Reliant Pharmaceuticals.

[2] Subsequently, Reliant developed the oral solution of Axid, marketing this in 2004, after gaining approval from the

U.S. Food and Drug Administration (FDA).

[3] However, a year later, they sold rights of the Axid Oral Solution (including the issued patent

[4] protecting the product) to Braintree Laboratories.

[5]

Nizatidine proved to be the last new histamine H

2 receptor antagonist introduced prior to the advent of

proton pump inhibitors.'

Nizatidine, the systematic chemical name of which is

N-[2-[[[2-[ imemylammo)memyl]-4-tl iazolyl]memyl]mio]e yl]--N'-

methyl-2-nitro-l,l-ethenecliamine, which has the formula (I).This

compound is a histamine H

2-receptor antagonist which is useful as anti- ulcer agents capable of inmbiting gastric acid secretion in mammals.

United States Patent No. 4,375,547; 4587344, 4777260;

4,904,792 and 5334725 discloses Nizatidine and other related products.

The synthesis of nizatidine disclosed in US patent No. 4,904,792

involves a multi-step process. The first step of the process comprises

reacting dimethylaminotmoacetamide hydrochloride with ethyl

bromopyruvate to obtain 2-(dinιethylaminon ethyl)-4-thiazolecarboxylate.

Reduction of this 4- tbiazolecarboxylate derivative with lithium

triethylborohydride gives 2-

(<-Umethylaminoπιethyl)-4-tI-ύazolenιethanol, which is then converted into 4-

(2-ammoetϊhyl)ti omethyl-2-d by reacting with

2-aminoethanethiol hydrochloride (cysteamine

hydrochloride). This 2- ό-imetihylan-ιinoπιethylthiazol derivative is

then converted into Nizatidine by reacting

.with

N-met-hyl-l-methyltHo-2-mt-coet-hyleneamine in the presence of an acid

United States Patent No. 4,382,090 describes a method to prepare 4-

(2-aminoethyl)tMome1_hyl-2-din ethylaminon etihyltl

iazol by fusing 4- cmoronιe yl-2-d- nethylaminonιet-hylthiazole with

cysteamine hydrochloride at above 100 °C.

United States Patent No. 4,468,517 described a method

to prepare 4- cldoronιethyl-2-<-ιimethylaminon et-hylt-lιiazole. The

method described in this patent involved reaction of

dimet-hylaminotmoacetamide hydrochloride with 1,3-dichloroacetone in

haloalkane (1,2-dichloroethane) as a solvent to obta

4-cHoromethyl^-hydroxy-2-dimet^ This 2-thiazoline derivative is then

dehydrated with a dehydrating agent like PC1

3, PBr

3, SOCl

2, POCl

3 etc., to get 4-chloromethyl-2- din etihyl-in monietihylthiazole.

European Patent Application EP 0,515,121 and EP

0,960,880 describe the process for the preparation of

2-(dim.et-hylarninomethyl)-4- thiazolemethanol. The process consists of

reacting (-Umethylaminothioacetamide hydrochloride with

1,3-dichloroacetone in toluene to get

4-chlorometiιyl-4-hyαioxy-2-d-methylaminomethyl-2- thiazoline, which is

then reacted with alkali metal base in an inert solvent such as toluene

to get 2-(dimethylam-m.omethyl)-4-thiazolemethanol.

The methods described in United States Patent No.

4,468,517 for the synthesis of 4-chloromethyl-4-hy(

oxy-2-dimethyl-ui-momethyl-2- thiazoline, requires complete evaporation

of the solvent 1,2-dichloroethane to get the crude product; it is then

washed with ethyl acetate to obtain a

pure product. Evaporation of the solvent to complete dryness is an

inconvenient and inappropriate operation in large-scale manufacturing.

Such evapprations in large-scale operations would produce the solids as

lumps; further washing such lumps with solvents would be ineffective due

to improper -mixing of -the solid -with solvent. The method described

in EP 0,515,121 and EP 0,960,880 for the synthesis of

4-cHorometlιyl-4-hyc oxy*-2-α_im requires isolation of the product from

the reaction mixture by precipitation of the product from the mother

liquor by the addition of petroleum ether. The crude product obtained by

the precipitation is then subjected to an additional purification step

by crystallisation from toluene.

A number of procedures are described for the

preparation of dimethylammotmoacetamide. Examples are Japanese Patent

No. JP 62,273,948, JP 62,273,949, JP 02,264,755 and Org. Prep. Proced.

Int., 1992, 24, P.66-7. All the procedures described in the literature-

or the preparation of dirnethylaminotitioacetamide from dimethylam

oacetomtrile involve the use of hydrogen sulfide under pressure in the

presence of promoters or catalysts. The disadvantage with the use of

hydrogen sulfide is the difficulty it poses in handling commercial

quantities, as it is a very toxic gas. The object of the present

invention is to provide an improved manufactxiring process for

4-chloromethyl-4-hydr xy-2- di--netihylam omethyl-2-tibiazoline..

.

SYN2

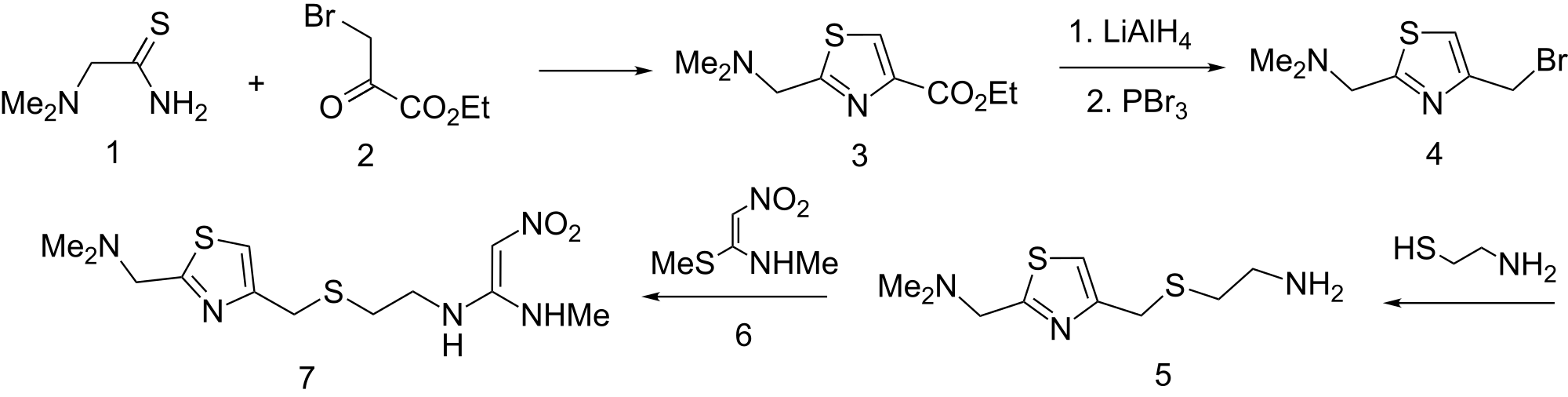

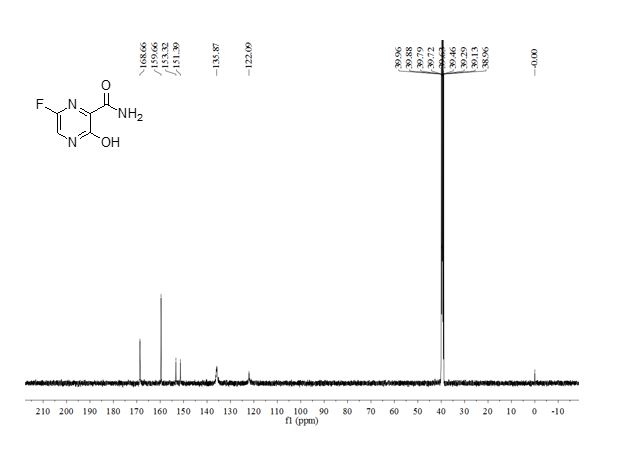

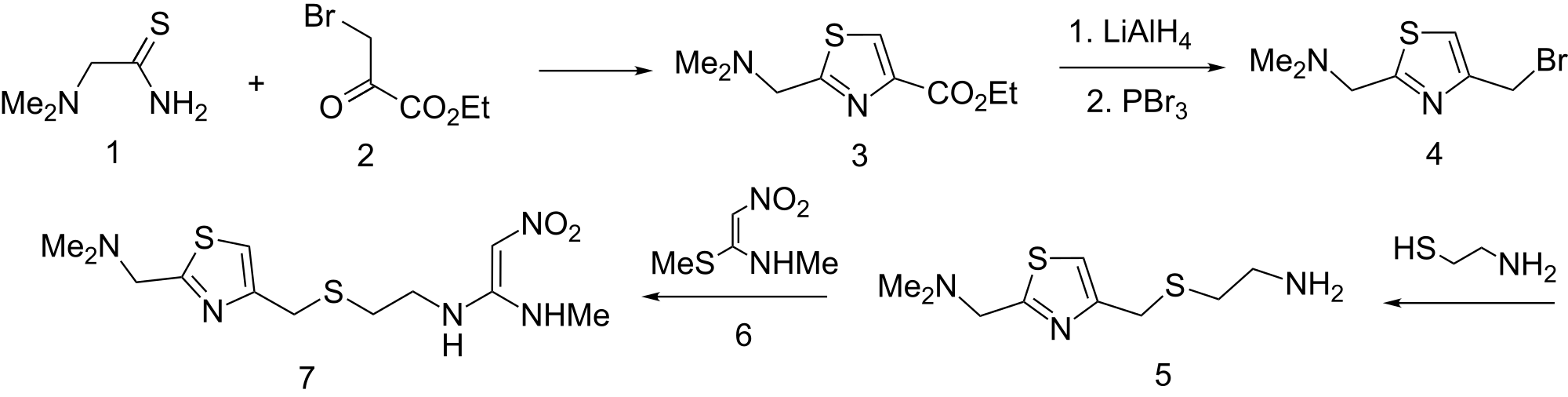

The cyclization of dimethylaminothioacetamide (I) with ethyl

bromopyruvate (II) in refluxing ethanol gives ethyl

2-(dimethylaminomethyl)-4-thiazolecarboxylate (III), which is reduced

with lithium triethyl borohydride in THF yielding

2-(dimethylaminomethyl)-4-thiazolemethanol (IV). The condensation of

(IV) with 2-aminoethanethiol (V) by means of 48% HBr affords

2-(dimethylaminomethyl)-4-(2-aminoethylthiomethyl)thiazole (VI), which

is finally condensed with 1-(methylthio)-2-nitro-N-methylethyleneamine

(VII) in water.

PATENT

http://www.google.com/patents/WO2004069817A1?cl=en

Example No: 1 Preparation of

dirnethylaniinothioacetaniide hydrochloride Into water (3000 ml),

phosphorus pentasulfi.de (1302 g; 2.93 mol) and dimethylam oacetonitrile

(1000 g; 11.88 mol) are added one after another at 10°C. The mixture is

then slowly warmed to 70°C and maintained for 3 hrs to complete the

reaction. The reaction mixture is then cooled to 20°C and sodiu

hydroxide (53% w/w, 2200 g, 29.15 mol) is added into it below 20°C. The

reaction mixture is then warmed to 50°C and extracted with toluene (2 x

2000 l). Isopropanolic hydrochloric acid (12% w/w; 3700 ml) is added

into the extract at 25 to 30°C to adjust the pH to 2 and the mass

stirred for 1 h to precipitate the product. The slurry is filtered,

washed with isopropyl alcohol (1000 ml) and dried to get (1360 g)

dimethyl ammotMoacetamide hydrochloride. Yield = 74.0%, HPLC purity =

97.6%

Example No: 2

Preparation of 4-chloromethyl-4-hydr oxy-2-dimethylaminomethyl-2- thiazoline

Dimethylam othioacetamide hydrochloride (1000 g; 6.472

mol) is suspended in diisopropyletiier (4000 ml). Added into this

suspension is sodium bicarbonate (1200 g; 14.28 mol) and sodium sulphate

(1000 g). The slurry is heated to 55-60° C and stirred for 1 hr. Into

this suspension is added 1,3 dichloroacetone (1000 g; 7.87 mol)

dissolved in diisopropylether (1000 ml). The reaction is continued at

50-55° C for 2 h. The progress of the reaction is monitored by a

qualitative HPLC analysis. Upon completion of the reaction, the reaction

mixture is

* filtered hot at 50-55° C to remove insoluble

inorganic salts. The mother liquor is cooled slowly to 0-5° C to

crystallize out the product. The product is then filtered and washed

with precooled diisopropylether (250 ml). The product is dried at 50° C

under reduced pressure to obtain 1120 g. Yield = 83%; HPLC purity =

98.2%. The following example illustrates the process to convert this

pure 4- cHoromethyl-4-hyσ-roxy-2-ά-imet^^ Nizatidine. Example No 3:

Preparation of N- [2- [ [ [2- [(Dimethylaι-nino)methyl] -4- thiazolyl]

methyl] thio] ethyl] -N'-methyl-2-nitro-l,l-ethenediamine. A.

Preparation of 4-chloromethyl-2-ααmethylam onιethylthiazole

Hydrochloride.

Thionyl chloride (430 ml; 5.9 mol) is added into

chloroform (1000 ml) and cooled to 20° C. Into this solution is added

4-chloromethyl-4- hyά^oxy-2-dinιethylam ome yl-2-thiazoline (1000 g;

4.79 mol), dissolved in chloroform (4000 ml). The reaction mixture is

further gradually heated to 60-65° C and maintained at this temperature

till qualitative HPLC analysis

shows the completion of the reaction. The reaction mixture is then

cooled slowly to 30° C to get the product crystallized out. The product

is filtered, washed and dried under reduced pressure to obtain 900 g of

pure product. Yield = 83.3 %. B. Preparation of 4-(2-am

oethyl)thiomethyl-2- ά-imethylam omethylthiazole.

2-A-minoethanetl iol hydrochloride (cysteamine

hydrochloride, 520 g; 4.5 mol) is suspended in water (500 ml). This

suspension is cooled to 5° C and sodium hydroxide solution (45 % w/w,

870 ml; 14.7 mol) is added into it at 5-10° C. Into this suspension,

hydroxylamine sulphate (100 g; 0.6 mol) is added and stirred. A solution

of 4-chloromethyl-2- di-n ethyl- inomethylthiazole hydrochloride (1000

g; 4.43 mol) dissolved in water (1250 ml) is prepared separately. This

solution is added into the said suspension below 10° C and the reaction

continued at 10° C for another 1 h. The completion of the reaction is

determined by qualitative HPLC. The reaction mixture is then diluted

with water (2000 ml), heated to 40-45° C and extracted with toluene (2 x

2000 ml). The toluene extract is treated with activated carbon at

40-45° C for 30 min. Activated carbon is removed by filtration through

hyflo bed and evaporated toluene from the filtrate under reduced

pressure at 60° C to obtain 910 g of the product. Yield = 88 %. C.

Preparation of N-(2-(((2-(Dimethylamino)methyl)-4-

tltiazolyl)m.ethyl)tltio)elhyl)-N'-methyl-2-nitro-l ,1 -etheneά-iamine

(Nizatidine).

N-methyl-l-methyltHo-2-mtroethyleneamine (NMSM, 610 g;

4.12 mol) is mixed with water (1500 ml), and the mixture is cool to

20-25° C. 4- (2-Am-hoethyl)d omethyl-2-<^ (1000 g; 4.32 mol)

dissolved in water (1500 ml) is added into this suspension at 20-25° C.

The reaction mixture is warmed to 30-35° C and continued the reaction

for

8 h. The progress of the reaction is monitored by qualitative HPLC

analysis. The reaction mixture is extracted with toluene (2 x 1000 ml),

and the aqueous layer is treated with activated carbon (50 g) at 55-60° C

for 30 min. Activated carbon is removed by filtration through hyflo bed

and the aqueous filtrate is extracted with chloroform (4 x 1000 ml)rThe

cHorόform extract is concentrated under reduced pressure at less than

50° C; ethyl acetate (3000 ml) is added into the concentrate and

reconcentrated. Acetone (300 ml), ethyl acetate (300 ml) is added into

the concentrate and cooled to 0-5° C to crystallize the product. The

product is filtered, washed with precooled ethyl acetate (250 ml), and

dried to obtain pure Nizatidine 1160 g. Yield = 81.0%; HPLC purity -=

99.3%.

References

"Nizatidine". Livertox.nih.gov. Retrieved 2015-10-11.

[1] Archived May 26, 2008 at the Wayback Machine

[2] Archived December 26, 2013 at the Wayback Machine

"United States Patent: 6930119". Patft.uspto.gov. Retrieved 2015-10-11.

External links

| US4468517 * | May 12, 1983 | Aug 28, 1984 | Eli Lilly And Company | Synthesis of thiazoles |

| US5457206 * | Jul 1, 1994 | Oct 10, 1995 | Eli Lilly And Company | Process for preparing intermediates to nizatidine and related compounds |

| Citing Patent | Filing date | Publication date | Applicant | Title |

|---|

| WO2015002150A1 | Jun 30, 2014 | Jan 8, 2015 | Shin Nippon Biomedical Laboratories, Ltd. | Novel compound, organic cation transporter 3 detection agent, and organic cation transporter 3 activity inhibitor |

[O-][N+](=O)\C=C(/NC)NCCSCc1nc(sc1)CN(C)C

Matmata — in Tunisia.

Matmatah, Qabis, Tunisia.

.

//

![]() qarqna) are a group of islands lying off the east coast of Tunisia in the Gulf of Gabès, at 34°42′N 11°11′E. The Islands are low-lying, being no more than 13 metres (43 feet) above sea level. The main islands are Chergui and Gharbi. The archipelago has an area of 160 square kilometres (62 sq mi) and a population of 15,501 (2014).[2]

qarqna) are a group of islands lying off the east coast of Tunisia in the Gulf of Gabès, at 34°42′N 11°11′E. The Islands are low-lying, being no more than 13 metres (43 feet) above sea level. The main islands are Chergui and Gharbi. The archipelago has an area of 160 square kilometres (62 sq mi) and a population of 15,501 (2014).[2]

.

.

.

.