SORRY.........WILL BE UPDATED ............IN DRAFT MODE

memantine hydrochloride is as illustrated below.

Formula: Ci

2H

22CIN Molecular weight: 215.81 U.S. Patent No. 3,391,142

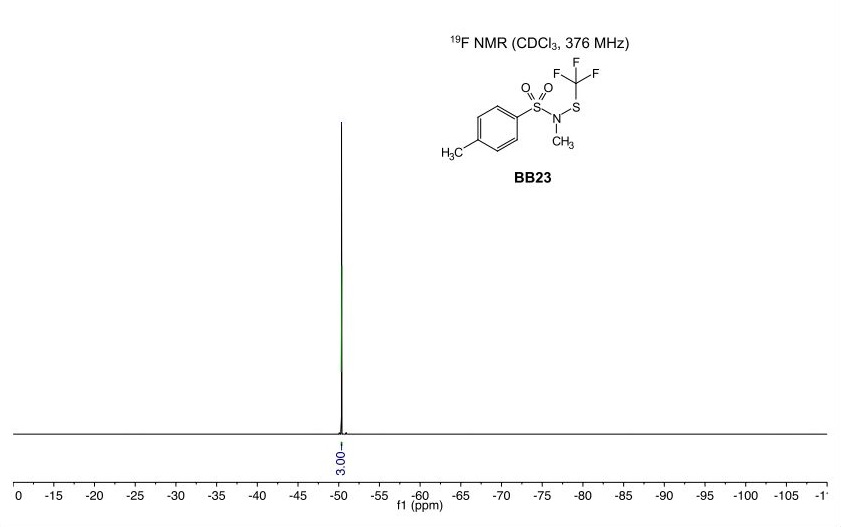

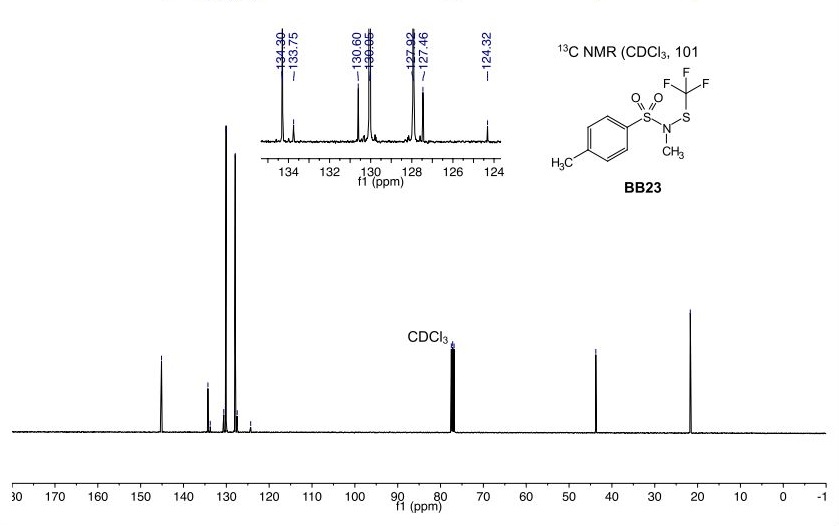

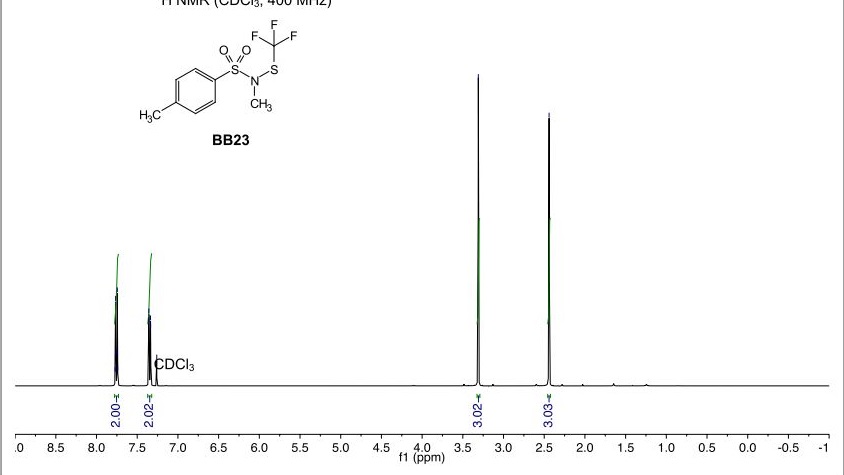

NMR......

http://file.selleckchem.com/downloads/nmr/S204301-Memantine-HCl-HNMR-Selleck.pdf

HPLC

http://file.selleckchem.com/downloads/hplc/S204301-Memantine-hydrochloride-Namenda-HPLC-Selleck.pdf

| Molecular Weight (MW) |

215.76 |

|---|

| Formula |

C12H21N.HCl |

| CAS No. |

41100-52-1 |

.......................................................................

IF THERE IS ONE METHYL EXTRA

Example 7: l-Amino-3.5.7-trimethyladamantane hydrochloride (Me-MMN*HC1) synthesis

16.2 g (20 ml) of n-butanol, 2.3 g of

l-acetamido-3,5,7-dimethyladamantane, and 3.6 g of 89.9% potassium

hydroxide were added to a 50 ml reactor equipped with a

condenser, a mechanical stirrer, and a thermometer at 20-25

0C under nitrogen. After addition, the internal temperature rises to 40-45

0C

without external cooling. The resulting suspension is heated to

128-132°C over 20-30min and a solution is obtained. After 15hrs at

128-132°C (slight reflux), the reaction is considered to be complete

(unreacted 1- acetamido-3,5,7-dirnethyladarnantane less than 5%).

After cooling to 45-50

0C, water (20ml) is added to form a biphasic system. After stirring (5min) and standing (15min) at 20-25

0C

phases are separated. The aqueous phase is discarded and the organic

phase is washed with water (2 x 20 ml). The obtained organic solution is

acidified with HCl to pH 1 and the solution is concentrated under

vacuum until a semisolid is obtained. At this point, after cooling to

45-50

0C, ethyl acetate (40ml) is added. The obtained

suspension is cooled to 0±3°C and after 3hrs the suspension is filtered

and the recovered solid is washed three times with ethyl acetate (6ml

each). Wet white solid is dried under vacuum at 55-60

0C for 15hrs. Dry weight, 1.93g.

1H NMR is reported:

1H-NMR in CD

3OD (298K)

http://www.google.com.ar/patents/EP1999100A1?cl=en

http://www.google.com.ar/patents/EP1999100A1?cl=en

Memantine hydrochloride, l-amino-3,5-dimethyladamantane

hydrochloride, is one of a small group of drugs known as Tricyclic

Antivirals (TAVs), and provides good and persistent activation of

central nervous system N-methyl-d-aspartate (NMDA) receptors, such that

it can be used in the treatment of Parkinson's and Alzheimer's diseases.

The chemical structure of memantine hydrochloride is as illustrated

below.

Formula: Ci

2H

22CIN Molecular

weight: 215.81 U.S. Patent No. 3,391,142 ('"142 patent") discloses the

synthesis of memantine hydrochloride and its precursor,

l-acetamido-3,5-dimethyladamantane, according to following scheme.

In the first reaction, l-bromo-3,5-diτnethyladamantane

reacts with 17 moles of acetonitrile and 35 moles of sulphuric acid at

room temperature to give the crude intermediate product in 100 percent

yield. The intermediate product is subjected to alkaline hydrolysis with

sodium hydroxide in diethylene glycol by refluxing at a temperature

greater than 190

0C for six hours. The hydrolyzed product is

diluted with water, followed by several benzene extractions, and the

memantine free base is recovered by solvent distillation. The free base

is then diluted with ether, and the addition of hydrogen chloride gas

provides crude memantine hydrochloride. The crude product is then

crystallized from a mixture of ethanol and ether. The '142 patent also

discloses the compounds: l-bromo-3,5,7-trimethyladamantane

(Br-TMAD) and l-bromo-3-methyladamantane (Br-MMAD)

U.S. Patent No. 5,061,703 also discloses the compounds:

l-Amino-3,5,7- trimethyladamantane hydrochloride (Me-MMN*HC1) and

l-Amino-3- methyladamantane hydrochloride (DesMe-MMN*HCl).

Like any synthetic compound, memantine hydrochloride

salt can contain extraneous compounds or impurities that can come from

many sources. They can be unreacted starting materials, by-products of

the reaction, products of side reactions, or degradation products.

Impurities in memantine hydrochloride salt or any active pharmaceutical

ingredient (API) are undesirable and, in extreme cases, might even be

harmful to a patient being treated with a dosage form containing the

API. It is also known in the art that impurities in an API may arise

from degradation of the API itself, which is related to the stability of

the pure API during storage, and the

manufacturing process, including the chemical synthesis. Process

impurities include unreacted starting materials, chemical derivatives of

impurities contained in starting materials, synthetic by-products, and

degradation products.

In addition to stability, which is a factor in the

shelf life of the API, the purity of the API produced in the commercial

manufacturing process is clearly a necessary condition for

commercialization. Impurities introduced during commercial manufacturing

processes must be limited to very small amounts, and are preferably

substantially absent. For example, the International Conference on

Harmonization of Technical Requirements for Registration for Human Use

("ICH") Q7A guidance for API manufacturers requires that process

impurities be maintained below set limits by specifying the quality of

raw materials, controlling process parameters, such as temperature,

pressure, time, and stoichiometric ratios, and including purification

steps, such as crystallization, distillation, and liquid-liquid

extraction, in the manufacturing process.

The product mixture of a chemical reaction is rarely a

single compound with sufficient purity to comply with pharmaceutical

standards. Side products and by-products of the reaction and adjunct

reagents used in the reaction will, in most cases, also be present in

the product mixture. At certain stages during processing of the API,

memantine hydrochloride, it must be analyzed for purity, typically, by

HPLC, TLC or GC analysis, to determine if it is suitable for continued

processing and, ultimately, for use in a pharmaceutical product. The API

need not be absolutely pure, as absolute purity is a theoretical ideal

that is typically unattainable. Rather, purity standards are set with

the intention of ensuring that an API is as free of impurities as

possible, and, thus, are as safe as possible for clinical use. As

discussed above, in the United States, the Food and Drug Administration

guidelines recommend that the amounts of some impurities be limited to

less than 0.1 percent.

Generally, side products, by-products, and adjunct

reagents (collectively "impurities") are identified spectroscopically

and/or with another physical method, and then associated with a peak

position, such as that in a chromatogram, or a spot on a TLC plate.

(Strobel p. 953, Strobel, H. A.; Heineman, W.R., Chemical

Instrumentation: A Systematic Approach, 3rd dd. (Wiley & Sons: New

York 1989)). Thereafter, the impurity can be identified, e.g., by its

relative position in the chromatogram, where the position in a

chromatogram is conventionally measured in minutes between injection of

the sample on

the column and elution of the particular component through the detector.

The relative position in the chromatogram is known as the "retention

time."

The retention time can vary about a mean value based

upon the condition of the instrumentation, as well as many other

factors. To mitigate the effects such variations have upon accurate

identification of an impurity, practitioners use the "relative retention

time" ("RRT") to identify impurities. (Strobel p. 922). The RRT of an

impurity is its retention time divided by the retention time of a

reference marker. It may be advantageous to select a compound other than

the API that is added to, or present in, the mixture in an amount

sufficiently large to be detectable and sufficiently low as not to

saturate the column, and to use that compound as the reference marker

for determination of the RRT.

Those skilled in the art of drug manufacturing research

and development understand that a compound in a relatively pure state

can be used as a "reference standard." A reference standard is similar

to a reference marker, which is used for qualitative analysis only, but

is used to quantify the amount of the compound of the reference standard

in an unknown mixture, as well. A reference standard is an "external

standard," when a solution of a known concentration of the reference

standard and an unknown mixture are analyzed using the same technique.

(Strobel p. 924, Snyder p. 549, Snyder, L.R.; Kirkland, J.J.

Introduction to Modern Liquid Chromatography, 2nd ed. (John Wiley &

Sons: New York 1979)). The amount of the compound in the mixture can be

determined by comparing the magnitude of the detector response. See also

U.S. Patent No. 6,333,198, incorporated herein by reference.

The reference standard can also be used to quantify the

amount of another compound in the mixture if a "response factor," which

compensates for differences in the sensitivity of the detector to the

two compounds, has been predetermined. (Strobel p. 894). For this

purpose, the reference standard is added directly to the mixture, and is

known as an "internal standard." (Strobel p. 925, Snyder p. 552).

The reference standard can serve as an internal

standard when, without the deliberate addition of the reference

standard, an unknown mixture contains a detectable amount of the

reference standard compound using the technique known as "standard

addition."

In the "standard addition technique", at least two samples are prepared

by adding known and differing amounts of the internal standard.

(Strobel pp. 391-393, Snyder pp. 571, 572). The proportion of the

detector response due to the reference standard present in the mixture

without the addition can be determined by plotting the detector response

against the amount of the reference standard added to each of the

samples, and extrapolating the plot to zero concentration of the

reference standard. (See, e.g., Strobel, Fig. 11.4 p. 392). The response

of a detector in GC or HPLC (e.g. UV detectors or refractive index

detectors) can be and typically is different for each compound eluting

from the GC or HPLC column. Response factors, as known, account for this

difference in the response signal of the detector to different

compounds eluting from the column.

As is known by those skilled in the art, the management

of process impurities is greatly enhanced by understanding their

chemical structures and synthetic pathways, and by identifying the

parameters that influence the amount of impurities in the final product.

Summary of the Invention In one embodiment the present

invention provides a process for preparing memantine HCl having less

than about 0.15% of one or both of of Ac-NH-TMAD and Ac- NH -MMAD

comprising measuring an amount of at least one or both of N-acetyl-1-

amino-3,5,7-trimethyladamantane (Ac-NH-TMAD) and N-acetyl-l-amino-3-

methyladamantane (Ac-NH -MMAD) in a batch of

l-acetamido-3,5-dimethyladamantane, selecting a batch of

l-acetamido-3,5-dimethyladamantane having less than about 0.15% of one

or both of of Ac-NH-TMAD or Ac-NH -MMAD and converting the selected

batch of l-acetamido-3,5-dimethyladamantane to memantine HCl containing

less than about 0.15% of at least one of DesMe-MMN HCl or MeMMN HCl.

In one embodiment the present invention provides a

process for preparing memantine HCl containing less than about 0.15% of

at least one of DesMe-MMN HCl or MeMMN HCl comprising measuring an

amount of one or both of l-bromo-3,5,7- trimetyladamantane (Br-TMAD) or

l-bromo-3-methyladamantane (Br-MMAD) in a batch of

l-bromo-3,5-dimethyladamantane, selecting a batch having one or both of

less than about 0.15% of Br-TMAD or less than about 0.20% area Br-MMAD

and converting the batch of l-bromo-3,5-dimethyladamantane to memantine

HCl containing less than about 0.15% of at least one of DesMe-MMN HCl

and MeMMN HCl.

In one embodiment the present invention provides a

process for reducing amount of impurities present in memantine HCl

comprising measuring an amount of at least one

or both of l-bromo-3,5,7-trimetyladamantane (Br-TMAD) and l-bromo-3-

methyladamantane (Br-MMAD) in a batch of l-bromo-3

55-dimethyladamantane,

selecting a batch having at least one of less than about 0.15% Br-TMAD

or less than about 0.20% area Br-MMAD as measured by gas chromatography,

and converting the batch of 1- bromo-3,5-dimethyladamantane to

l-acetamido-3,5-dimethyladamantane; measuring an amount of at least one

of N-acetyl-l-amino-3,5,7-trimethyladamantane (Ac-NH-TMAD) and

N-acetyl-l-amino-3-methyladamantane (Ac-NH -MMAD) in a batch of

1-acetamido- 3,5-dimethyladamantane, selecting a batch of

l-acetamido-3,5-dimethyladamantane having less than about 0.15% area by

gas chromatography of at least one of Ac-NH- TMAD and Ac-NH -MMAD and

converting the selected batch of l-acetamido-3,5- dimethyladamantane to

memantine HCl containing less than about 0.15% of at least one of

DesMe-MMN HCl and MeMMN HCl.

Alleppey kerala INDIA.....Alappuzha

en.wikipedia.org/wiki/Alappuzha

pronunciation (help·info)), also known as Alleppey, is the administrative headquarters of Alappuzha District of Kerala state of southern India. Alappuzha is the ...

.

Table in restaurant after eating fish, Alleppey, Kerala, India, South Asia,

PAGODA RESORTS ALLEPPEY KERALA INDIA

////////////

.

.